76 Series Casters

Heavy-Duty Kingpinless Casters

The 76 Series Kingpinless caster easily handles heavy loads, with up to 7000 lb. capacity, and we offer many different wheel configurations in 3” width to meet your needs. This built-to-last metal caster is designed with extended leads and stronger, thicker legs that really pull their weight under pressure. Swivel components come with lubricated fittings for simple maintenance in the field.

Features

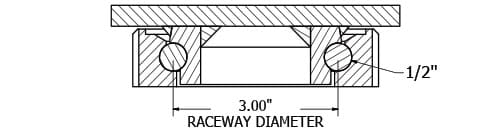

| Raceway Design | Patented Kingpinless™ single ball bearing precision machined raceway hardened to 53 Rockwell C minimum. Swivel section features 3” diameter raceway with ½” ball bearings. The notched raceway is standard. |

| Capacity | Up to 7000 lbs. |

| Leg Thickness | 3/8” |

| Axle | 3/4” bolt with lock or slotted nut as required |

| Finish | Laguna blue powder coat |

| Wheels | Wheels are available with either a 1” roller bearing which rotates on a hardened and ground spanner brushing or 3/4” tapered bearings that rotate on the axle. All wheels are equipped with lubricated fitting. |

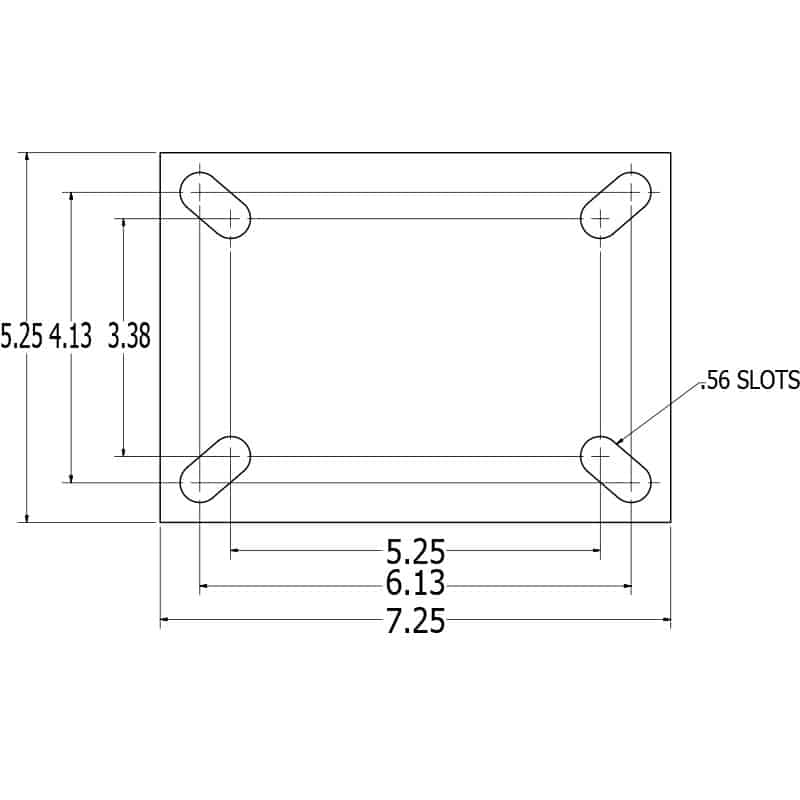

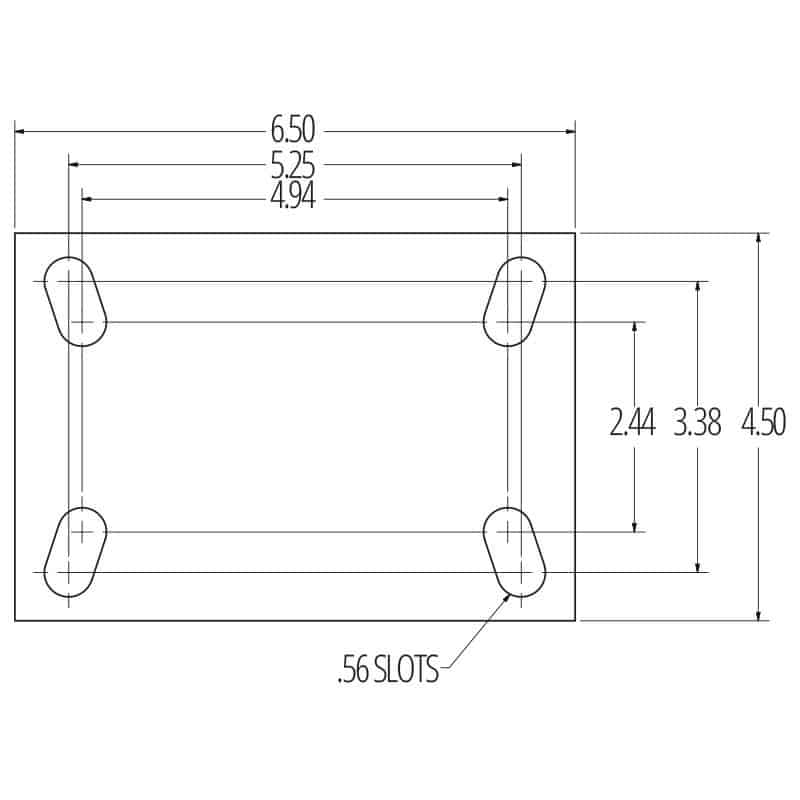

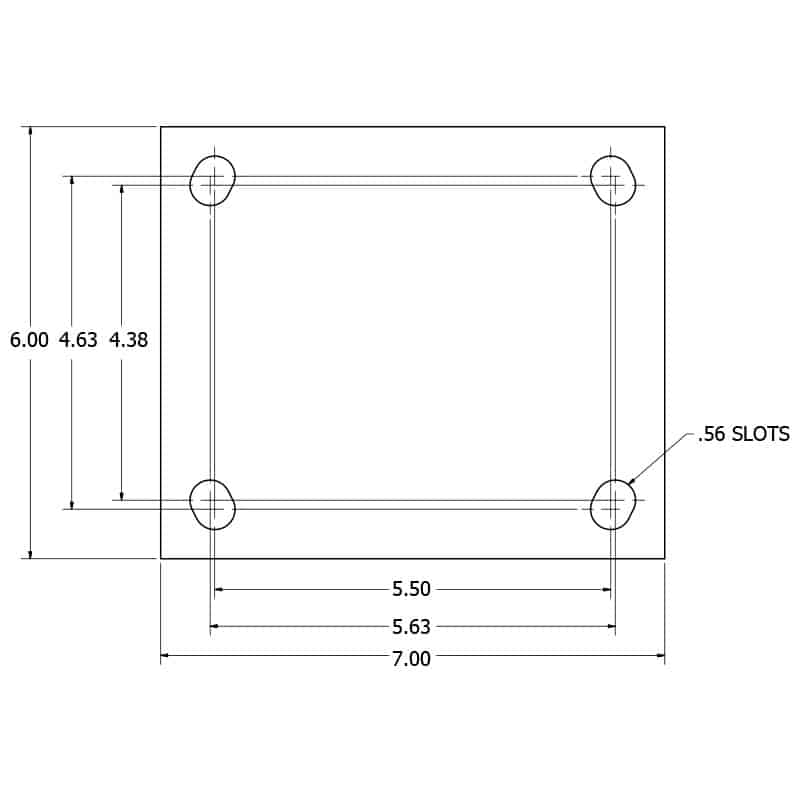

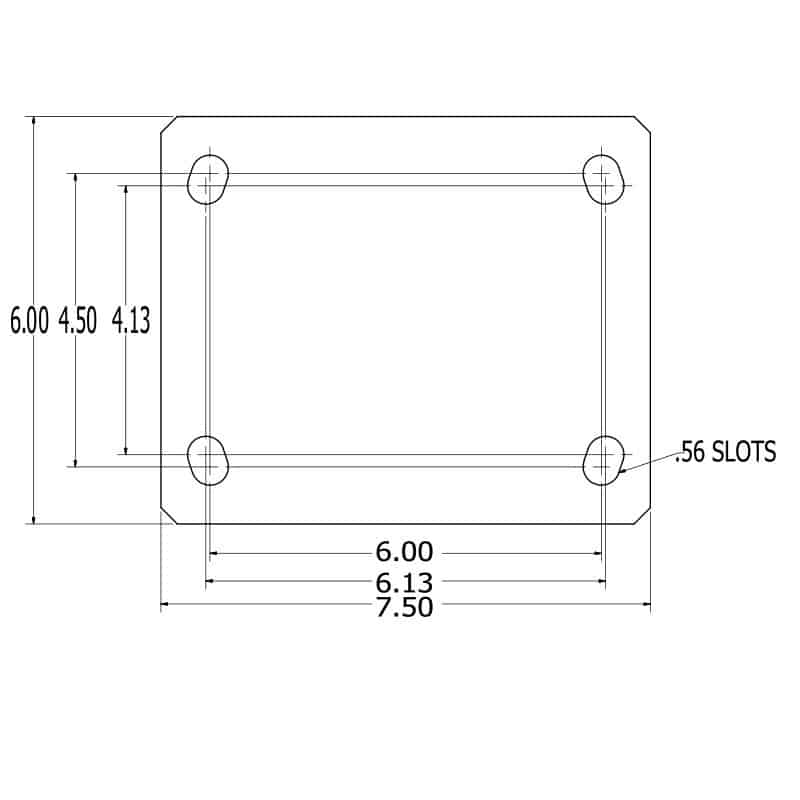

| Mounting Plate Size | 5-1/4” x 7-1/4” x 3/8” |

| Bolt Hole Spacing | 3-3/8” x 5-1/4” slotted to 4-1/8” x 6-1/8” |

| Mounting Bolt Diameter | 1/2” |

Applications

| Tow Lines | Boat & ship molding and building |

| Abusive Conditions | Storage tanks & gantries |

| Automotive | Shock load applications |

| Aerospace | Production line dollies |

| Metal fabricating | Heavy machinery |

| Military equipment | Mobile Homes |

| Tractor pulled trailers | Extreme duty platform trucks |

| Air cargo & ground support equipment | Heavy-duty processing equipment |

*Subtract 1/16" OAH when using this top plate

**Add 1/8" OAH when using this top plate

| CWB | Cam Wheel Brake |

| FICWB | Field Installable Cam Wheel Brake |

| MICWB | Metal Installable Cam Wheel Brake |

| PCWB | Poly Cam Wheel Brake |

| DSL | Demountable Swivel Lock |

| FOSL | Foot Operated Swivel Lock |

| LSL | L-Type Swivel Lock |

| SL | Swivel Lock |

| VSL | Vertical Swivel Lock |

| HT | High Temperature Lubrication |

| LT | Low Temperature Lubrication |

| HTP | High Temperature Paint |

| ZP | Zinc Plated |

| SR | Sealed Raceway |

| SWP | Sweeper Brush |

| WHEEL DIAMETER | WHEEL WIDTH | CAPACITY | WHEEL TYPE | OVERALL HEIGHT | ROLLER BEARING | STRAIGHT ROLLER BEARING | BALL BEARING | TAPERED BEARING | SWIVEL LEAD | APPROX WEIGHT |

|---|---|---|---|---|---|---|---|---|---|---|

| 5'' | 2-1/2'' | 2000 | Cast Iron | 7'' | 76-CIR-0525-S | 76-CIT-0525-S | 2'' | 18 | ||

| 6" | 2-1/2'' | 670 | Rubber on Iron | 8'' | 76-RIR-0625-S | 2-1/4'' | 16.5 | |||

| 6" | 2-1/2'' | 1080 | Rubber on Iron-EHT | 8'' | 76-RIR-0625-S-EHT | 76-RIT-0625-S-EHT | 2-1/4'' | 16.5 | ||

| 6" | 2-1/2'' | 1600 | Durastan | 8'' | 76-DUR-0625-S | 2-1/4'' | 11.5 | |||

| 6" | 2-1/2'' | 1620 | Urethane on Iron | 8'' | 76-UIR-0625-S | 76-UIT-0625-S | 2-1/4'' | 16.5 | ||

| 6" | 2-1/2'' | 1800 | Cast Iron | 8'' | 76-CIR-0625-S | 76-CIT-0625-S | 2-1/4'' | 17 | ||

| 6" | 2-1/2'' | 2500 | V-Groove Iron | 8'' | 76-VIR-0625-S | 76-VIT-0625-S | 2-1/4'' | 16.5 | ||

| 6" | 2-1/2'' | 5000 | Forged Steel | 8'' | 76-FSR-0625-S | 76-FST-0625-S | 2-1/4'' | 20.5 | ||

| 6" | 3'' | 680 | Rubber on Iron | 8'' | 76-RIR-0630-S | 2-1/4'' | 17.5 | |||

| 6" | 3'' | 1360 | Rubber on Iron-EHT | 8'' | 76-RIR-0630-S-EHT | 76-RIT-0630-S-EHT | 2-1/4'' | 17.5 | ||

| 6" | 3'' | 2000 | Durastan | 8'' | 76-DUR-0630-S | 2-1/4'' | 12.5 | |||

| 6" | 3'' | 2000 | Urethane on Iron | 8'' | 76-UIR-0630-S | 76-UIT-0630-S | 2-1/4'' | 17.5 | ||

| 6" | 3'' | 3000 | Cast Iron | 8'' | 76-CIR-0630-S | 76-CIT-0630-S | 2-1/4'' | 18.5 | ||

| 6" | 3'' | 7000 | Forged Steel | 8'' | 76-FSR-0630-S | 76-FST-0630-S | 2-1/4'' | 31 | ||

| 6" | 3'' | 7000 | Nylatron HD | 8'' | 76-NYB-0630-S | 2-1/4'' | 12.5 | |||

| 6" | 3″ | 7000 | V-Groove Forged | 8'' | 76-VFR-0630-S | 76-VFT-0630-S | 2-1/4'' | 30 | ||

| 8" | 2-1/2″ | 670 | Rubber on Iron | 10-1/2'' | 76-RIR-0825-S | 2-15/16'' | 18.5 | |||

| 8" | 2-1/2″ | 1340 | Rubber on Iron-EHT | 10-1/2'' | 76-RIR-0825-S-EHT | 76-RIT-0825-S-EHT | 2-15/16'' | 18.5 | ||

| 8" | 2-1/2″ | 2000 | Cast Iron | 10-1/2'' | 76-CIR-0825-S | 76 - CIT - 0825 - S | 2-15/16'' | 23 | ||

| 8" | 2-1/2″ | 2000 | Durastan | 10-1/2'' | 76-DUR-0825-S | 2-15/16'' | 15 | |||

| 8" | 2-1/2″ | 2000 | Urethane on Iron | 10-1/2'' | 76-UIR-0825-S | 76-UIT-0825-S | 2-15/16'' | 18.5 | ||

| 8" | 2-1/2″ | 2400 | GT | 10-1/2'' | 76-GTB-0825-S | 2-15/16'' | 15 | |||

| 8" | 2-1/2″ | 3000 | V-Groove Iron | 10-1/2'' | 76-VIR-0825-S | 76-VIT-0825-S | 2-15/16'' | 27 | ||

| 8" | 2-1/2″ | 4500 | Forged Steel | 10-1/2'' | 76-FSR-0825-S | 76-FST-0825-S | 2-15/16'' | 25.5 | ||

| 8" | 3″ | 840 | Rubber on Iron | 10-1/2'' | 76-RIR-0830-S | 2-15/16'' | 19.5 | |||

| 8" | 3″ | 1500 | Rubber on Aluminum-EHT | 10-1/2'' | 76-RAB-0830-S-EHT | 76-RAT-0830-S-EHT | 2-15/16'' | 14 | ||

| 8" | 3″ | 1600 | Omega | 10-1/2'' | 76-UOR-0830-S | 76-UOB-0830-S | 76-UOT-0830-S | 2-15/16'' | 19 | |

| 8" | 3″ | 1680 | Rubber on Iron-EHT | 10-1/2'' | 76-RIR-0830-S-EHT | 76-RIT-0830-S-EHT | 2-15/16'' | 19.5 | ||

| 8" | 3″ | 2500 | Durastan | 10-1/2'' | 76-DUR-0830-S | 2-15/16'' | 16.5 | |||

| 8" | 3″ | 2500 | Urethane on Iron | 10-1/2'' | 76-UIR-0830-S | 76-UIT-0830-S | 2-15/16'' | 19.5 | ||

| 8" | 3″ | 3000 | Cast Iron | 10-1/2'' | 76-CIR-0830-S | 76-CIT-0830-S | 2-15/16'' | 26 | ||

| 8" | 3″ | 4000 | Infinity | 10-1/2'' | 76-UIB-0830-S-INF | 2-15/16'' | 20 | |||

| 8" | 3″ | 5500 | Forged Steel | 10-1/2'' | 76-FSR-0830-S | 76-FST-0830-S | 2-15/16'' | 26 | ||

| 8" | 3″ | 7000 | Nylatron HD | 10-1/2'' | 76-NYB-0830-S | 2-15/16'' | 16 | |||

| 8" | 3″ | 5000 | V-Groove Iron | 10-1/2'' | 76-VIR-0830-S | 76-VIT-0830-S | 2-15/16'' | 26 | ||

| 8" | 3″ | 6000 | V-Groove Forged | 10-1/2'' | 76-VFR-0830-S | 76-VFT-0830-S | 2-15/16'' | 36 | ||

| 10" | 2-1/2″ | 790 | Rubber on Iron | 12-1/2'' | 76-RIR-1025-S | 3-3/8″ | 21.5 | |||

| 10" | 2-1/2″ | 1580 | Rubber on Iron-EHT | 12-1/2'' | 76-RIR-1025-S-EHT | 76-RIT-1025-S-EHT | 3-3/8″ | 21.5 | ||

| 10" | 2-1/2″ | 2370 | Urethane on Iron | 12-1/2'' | 76-UIR-1025-S | 76-UIT-1025-S | 3-3/8″ | 21.5 | ||

| 10" | 2-1/2″ | 2500 | Cast Iron | 12-1/2'' | 76-CIR-1025-S | 76-CIT-1025-S | 3-3/8″ | 25.5 | ||

| 10" | 2-1/2″ | 2500 | Durastan | 12-1/2'' | 76-DUR-1025-S | 3-3/8″ | 16.5 | |||

| 10" | 3″ | 1000 | Rubber on Iron | 12-1/2'' | 76-RIR-1030-S | 3-3/8″ | 22.5 | |||

| 10" | 3″ | 2000 | Omega | 12-1/2'' | 76-UOR-1030-S | 76-UOB-1030-S | 76-UOT-1030-S | 3-3/8″ | 22 | |

| 10" | 3″ | 2000 | Rubber on Aluminum-EHT | 12-1/2'' | 76-RAB-1030-S-EHT | 76-RAT-1030-S-EHT | 3-3/8″ | 20.3 | ||

| 10" | 3″ | 2000 | Rubber on Iron-EHT | 12-1/2'' | 76-RIR-1030-S-EHT | 76-RIT-1030-S-EHT | 3-3/8″ | 22.5 | ||

| 10" | 3″ | 2900 | Durastan | 12-1/2'' | 76-DUR-1030-S | 3-3/8″ | 20 | |||

| 10" | 3″ | 3000 | Urethane on Iron | 12-1/2'' | 76-UIR-1030-S | 76-UIT-1030-S | 3-3/8″ | 22.5 | ||

| 10" | 3″ | 3400 | GT | 12-1/2'' | 76-GTB-1030-S | 3-3/8″ | 20 | |||

| 10" | 3″ | 3400 | Ultra Thick Urethane | 12-1/2'' | 76-UTR-1030-S | 76-UTT-1030-S | 3-3/8″ | 26 | ||

| 10" | 3″ | 4000 | Cast Iron | 12-1/2'' | 76-CIR-1030-S | 76-CIT-1030-S | 3-3/8″ | 23 | ||

| 10" | 3″ | 5000 | Infinity | 12-1/2'' | 76-UIB-1030-S-INF | 3-3/8″ | 23 | |||

| 10" | 3″ | 5000 | V-Groove Iron | 12-1/2'' | 76-VIR-1030-S | 76-VIT-1030-S | 3-3/8″ | 23 | ||

| 10" | 3'' | 6000 | V-Groove Forged | 12-1/2'' | 76-VFR-1030-S | 76-VFT-1030-S | 3-3/8'' | 48 | ||

| 10" | 3″ | 6000 | Forged Steel | 12-1/2'' | 76-FSR-1030-S | 76-FST-1030-S | 3-3/8″ | 41 | ||

| 10" | 3″ | 7000 | Nylatron HD | 12-1/2'' | 76-NYB-1030-S | 3-3/8″ | 21 | |||

| 12" | 2-1/2″ | 900 | Rubber on Iron | 15-1/2'' | 76-RIR-1225-S | 76-RIT-1225-S | 4-5/16″ | 23.5 | ||

| 12" | 2-1/2″ | 2700 | Urethane on Iron | 15-1/2'' | 76-UIR-1225-S | 4-5/16″ | 23.5 | |||

| 12" | 2-1/2″ | 3000 | Durastan | 15-1/2'' | 76-DUR-1225-S | 4-5/16″ | 20.5 | |||

| 12" | 3″ | 1140 | Rubber on Iron | 15-1/2'' | 76-RIR-1230-S | 76-RIT-1230-S | 4-5/16″ | 26.5 | ||

| 12" | 3″ | 2280 | Rubber on Aluminum-EHT | 15-1/2'' | 76-RAB-1230-S-EHT | 76-RAT-1230-S-EHT | 4-5/16″ | 24.5 | ||

| 12" | 3″ | 2280 | Rubber on Iron-EHT | 15-1/2'' | 76-RIR-1230-S-EHT | 76-RIT-1230-S-EHT | 4-5/16″ | 26.5 | ||

| 12" | 3″ | 3400 | Urethane on Iron | 15-1/2'' | 76-UIR-1230-S | 76-UIT-1230-S | 4-5/16″ | 26.5 | ||

| 12" | 3″ | 3500 | Durastan | 15-1/2'' | 76-DUR-1230-S | 4-5/16″ | 22.5 | |||

| 12" | 3″ | 4100 | Ultra Thick Urethane | 15-1/2'' | 76-UTR-1230-S | 76-UTT-1230-S | 4-5/16″ | 29 | ||

| 12" | 3″ | 5000 | Cast Iron | 15-1/2'' | 76-CIR-1230-S | 76-CIT-1230-S | 4-5/16″ | 32 | ||

| 12" | 3″ | 6000 | V-Groove | 15-1/2'' | 76-VIR-1230-S | 76-VIT-1230-S | 4-5/16″ | 43 | ||

| 12" | 3″ | 7000 | Nylatron HD | 15-1/2'' | 76-NYB-1230-S | 4-5/16″ | 26 |

To order a rigid caster, change the “S” to “R” in the model number. For example: “75-CIR-1030-R.” To order a rig only, omit the blue letters. For example: “75-1030-S.” Dimensions shown are nominal. If precise dimensions are required, consult your RWM representative. For approximate weight of our rigid caster, deduct 3.9 pounds.

Case Hardened Kingpinless Casters — for Strength You Can Count On

The case hardened 76 Series caster provides maximum service life, making this an extremely cost-effective product. These Kingpinless metal heavy-duty casters eliminate cracking risks, unlike the often-unreliable through-hardened or induction-hardened casters that other manufacturers offer.

- Case hardening, also called surface hardening or carburizing, is a superior process used here at RWM. Case hardening is a thermochemical method that reinforces metal casters by adding a layer of another, more durable metal alloy. This increases hardness on the outside, while the inner, low-carbon core remains slightly softer, to counteract any brittleness. This makes our casters stand up to heavy loads and long-term use without cracking.

- Through hardening is the process of using rapid heating and quenching (cooling in water or oil) metal to increase steel hardness. This process can leave the metal caster somewhat brittle, and prone to breaking under stress, unfortunately.

- Induction hardening exposes metal caster parts to electromagnetic energy creating an alternating current in the caster component. This heats the metal but typically hardens only a certain area, leaving other areas somewhat weaker and vulnerable to cracking and breaking.

Top Applications for 76 Series Casters

These case-hardened heavy-duty casters work well for industrial towing operations in automotive assembly lines and tire manufacturing plants, boat and shipbuilding, as well as other heavy commercial applications that call for an incredibly strong and reliable product. What’s more, our 76 Series industrial casters are proudly made in the USA!

Why Buy From RWM?

With our huge stock of caster components and wheel options on hand, we can custom create the exact type and feature set that you require. This system allows us to meet tight product delivery deadlines with the highest-quality standards in heavy-duty caster manufacturing. We inspect and ship our custom casters properly lubricated, so you can use them immediately and keep maintenance tasks to a minimum.

At RWM, we are dedicated to making your job easier. We understand your need for strong, easily maneuverable, and extremely durable casters like the 76 Series. We supply only the best caster products in order to keep your business moving at pace and to help it grow in a competitive environment.

Purchase your Kingpinless casters from the most capable and experienced supplier of quality casters—RWM. Contact us at 800-634-7704 today.