V-Groove Wheels

VF and VI Wheels

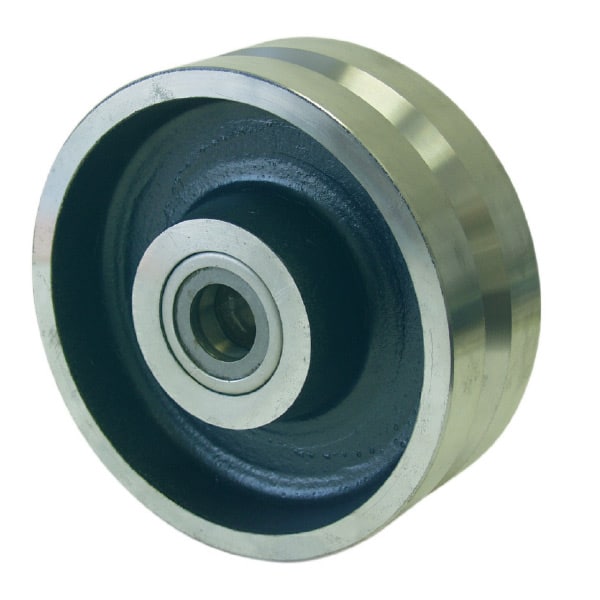

RWM Casters V-Groove industrial track wheels are high-strength cast-iron (VI) castings or forged steel (VF) forgings machined with a 90-degree groove for operation on an inverted angle iron track. Care must be taken to ensure the inverted angle iron track is parallel for smooth and constant tracking. In some cases, it may be advisable to run inverted angle iron on one side with V-groove wheels and flat bar stock steel on the other side with a flat-faced cast-iron or forged steel wheel.

Features

| Wheel Bearings | Choice of straight roller bearing or tapered bearing |

| Temperature Range | -50° to +800°F |

| Hub Length | Can be cut or lengthened with spacers |

| Lubrication Fittings | Standard on 2-1/2″ and wider wheels |

| Bores | Various sizes available on some wheels |

| Keyways | Can be installed on most sizes |

Applications

V-Groove Wheels are used to control the flow of a load, for example, into an oven, between machines, over long distances, or where a “production line” sequence is required. |

| WS | Wheel Seals |

| ZF | Zerk Fittings on 2″ wide and smaller wheels |

| WHEEL DIAMETER | WHEEL WIDTH | CAPACITY | WHEEL TYPE | AXLE DIAMETER | STRAIGHT ROLLER BEARING | TAPERED BEARING | GROOVE WIDTH | GROOVE DEPTH | HUB LENGTH | APPROX WEIGHT |

|---|---|---|---|---|---|---|---|---|---|---|

| 4'' | 1-1/2" | 700 | 1/2″ | VIR-0415-08 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 1-1/2" | 700 | 5/8″ | VIR-0415-10 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 1-1/2" | 700 | 3/4″ | VIR-0415-12 | 7/8" | 7/16" | 1-7/8″ | 3.4 | ||

| 4'' | 2" | 800 | 1/2″ | VIR-0420-08 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 4'' | 2" | 800 | 5/8″ | VIR-0420-10 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 4'' | 2" | 800 | 3/4″ | VIR-0420-12 | 7/8" | 7/16" | 2-7/16″ | 4.5 | ||

| 5'' | 2" | 800 | 1/2″ | VIR-0520-08 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 5'' | 2" | 800 | 5/8″ | VIR-0520-10 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 5'' | 2" | 800 | 3/4″ | VIR-0520-12 | 7/8" | 7/16" | 2-7/16″ | 6.3 | ||

| 6" | 2" | 1000 | 1/2″ | VIR-0620-08 | VIT-0620-08 | 7/8" | 7/16" | 2-7/16″ | 7.2 | |

| 6" | 2" | 1000 | 5/8″ | VIR-0620-10 | 7/8" | 7/16" | 2-7/16″ | 7.2 | ||

| 6" | 2" | 1000 | 3/4″ | VIR-0620-12 | VIT-0620-12 | 7/8" | 7/16" | 2-7/16″ | 7.2 | |

| 6" | 2-1/2'' | 1500 | 3/4″ | VIR-0625-12-YY | VIT-0625-12-YY | 7/8" | 7/16" | 3″ | 11.2 | |

| 6" | 2-1/2'' | 1500 | 1″ | VIR-0625-16-SI-YY | 7/8" | 7/16" | 3″ | 11.2 | ||

| 6" | 2-1/2'' | 1500 | 1″ | VIR-0625-16-YY | VIT-0625-16-YY | 7/8" | 7/16" | 3″ | 11.2 | |

| 6" | 2-1/2'' | 1500 | 1-1/4″ | VIR-0625-20-YY | 7/8" | 7/16" | 3″ | 11.2 | ||

| 6" | 2-1/2'' | 2500 | 3/4″ | VIR-0625-12 | VIT-0625-12 | 7/8" | 7/16" | 3-1/2″ | 11.2 | |

| 6" | 2-1/2'' | 2500 | 1″ | VIR-0625-16-SI | 7/8" | 7/16" | 3-1/2″ | 11.2 | ||

| 6" | 2-1/2'' | 2500 | 1″ | VIR-0625-16 | VIT-0625-16 | 7/8" | 7/16" | 3-1/2″ | 11.2 | |

| 6" | 2-1/2'' | 2500 | 1-1/4″ | VIR-0625-20 | 7/8" | 7/16" | 3-1/2″ | 11.2 | ||

| 6" | 3'' | 3500 | 3/4″ | VIR-0630-12 | VIT-0630-12 | 7/8" | 7/16" | 3-1/2″ | 20 | |

| 6" | 3'' | 3500 | 1″ | VIR-0630-16 | VIT-0630-16 | 7/8" | 7/16" | 3-1/2″ | 20 | |

| 6" | 3'' | 3500 | 1″ | VIR-0630-16-SI | 7/8" | 7/16" | 3-1/2″ | 20 | ||

| 6" | 3'' | 3500 | 1-1/4″ | VIR-0630-20 | 7/8" | 7/16" | 3-1/2″ | 20 | ||

| 6" | 3'' | 7000 | 3/4″ | VFR-0630-12 | VFT-0630-12 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 7000 | 1″ | VFT-0630-16 | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 6" | 3'' | 7000 | 1″ | VFR-0630-16-SI | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 6" | 3'' | 7000 | 1-1/4″ | VFR-0630-20 | VFT-0630-20 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 7000 | 1-1/2″ | VFR-0630-24 | VFT-0630-24 | 1-3/8" | 11/16" | 3-1/2″ | 30 | |

| 6" | 3'' | 10000 | 1-1/4″ | VFT-0630-20-HD | 1-3/8" | 11/16" | 3-1/2″ | 30 | ||

| 8" | 2" | 1050 | 1/2″ | VIR-0820-08 | VIT-0820-08 | 7/8" | 7/16" | 2-7/16″ | 13.2 | |

| 8" | 2" | 1050 | 5/8″ | VIR-0820-10 | 7/8" | 7/16" | 2-7/16″ | 13.2 | ||

| 8" | 2" | 1050 | 3/4″ | VIR-0820-12 | VIT-0820-12 | 7/8" | 7/16" | 2-7/16″ | 13.2 | |

| 8" | 2-1/2'' | 3000 | 3/4″ | VIR-0825-12 | VIT-0825-12 | 7/8" | 7/16" | 3-1/2″ | 15.8 | |

| 8" | 2-1/2'' | 3000 | 1″ | VIR-0825-16-SI | 7/8" | 7/16" | 3-1/2″ | 15.8 | ||

| 8" | 2-1/2'' | 3000 | 1″ | VIR-0825-16 | VIT-0825-16 | 7/8" | 7/16" | 3-1/2″ | 15.8 | |

| 8" | 2-1/2'' | 3000 | 1-1/4″ | VIR-0825-20 | 7/8" | 7/16" | 3-1/2″ | 15.8 | ||

| 8" | 3'' | 5000 | 3/4″ | VIR-0830-12 | VIT-0830-12 | 7/8" | 7/16" | 3-1/2″ | 23.5 | |

| 8" | 3'' | 5000 | 1″ | VIR-0830-16-SI | 7/8" | 7/16" | 3-1/2″ | 23.5 | ||

| 8" | 3'' | 5000 | 1″ | VIR-0830-16 | VIT-0830-16 | 7/8" | 7/16" | 3-1/2″ | 23.5 | |

| 8" | 3'' | 5000 | 1-1/4″ | VIR-0830-20 | 7/8" | 7/16" | 3-1/2″ | 23.5 | ||

| 8" | 6000 | 3/4″ | VFR-0830-12 | VFT-0830-12 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1″ | VFR-0830-16-SI | VFT-0830-16 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1-1/4″ | VFR-0830-20 | VFT-0830-20 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 6000 | 1-1/2″ | VFR-0830-20-SI | 7/8" | 7/16" | 3-1/2″ | 30 | |||

| 8" | 3'' | 6000 | 1-1/2″ | VFR-0830-24 | 7/8" | 7/16" | 3-1/2″ | 30 | ||

| 8" | 4" | 10000 | 1-1/4″ | VFR-0840-20-SI | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 10000 | 1-1/2″ | VFR-0840-24-SI | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 10000 | 2″ | VFR-0840-32 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 15000 | 1-1/4″ | VFT-0840-20 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 8" | 4" | 15000 | 1-1/2″ | VFT-0840-24 | 1-3/4" | 7/8" | 4-1/2″ | 30 | ||

| 10" | 3'' | 5000 | 3/4″ | VIR-1030-12 | VIT-1030-12 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 5000 | 1″ | VIR-1030-16-SI | 7/8" | 7/16" | 3-1/2″ | 21 | ||

| 10" | 3'' | 5000 | 1″ | VIR-1030-16 | VIT-1030-16 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 5000 | 1-1/4″ | VIR-1030-20 | VIT-1030-20 | 7/8" | 7/16" | 3-1/2″ | 21 | |

| 10" | 3'' | 6000 | 3/4″ | VFR-1030-12 | VFT-1030-12 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 3'' | 6000 | 1″ | VFR-1030-16 | VFT-1030-16 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 3'' | 6000 | 1″ | VFR-1030-16-SI | 1-3/8" | 11/16" | 3-1/2″ | 31 | ||

| 10" | 3'' | 6000 | 1-1/4″ | VFR-1030-20 | VFR-1030-20 | 1-3/8" | 11/16" | 3-1/2″ | 31 | |

| 10" | 4" | 10000 | 1-1/4″ | VFR-1040-20-SI | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 10000 | 1-1/2″ | VFR-1040-24-SI | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 10000 | 2″ | VFR-1040-32 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 15000 | 1-1/4″ | VFT-1040-20 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 10" | 4" | 15000 | 1-1/2″ | VFT-1040-24 | 1-3/4" | 7/8" | 4-1/2″ | 38 | ||

| 12" | 3'' | 6000 | 3/4″ | VIR-1230-12 | VIT-1230-12 | 7/8" | 7/16" | 3-1/2″ | 39 | |

| 12" | 3'' | 6000 | 1″ | VIR-1230-16 | VIT-1230-16 | 7/8" | 7/16" | 3-1/2″ | 39 | |

| 12" | 3'' | 6000 | 1″ | VIR-1230-16-SI | 7/8" | 7/16" | 3-1/2″ | 39 |

V-Groove Wheels

Features of V-Groove Wheels

At RWM, our V-groove wheels are available with wheel diameters ranging from 4 to 12 inches. Our wheels are available in widths ranging from 1.5 to 3 inches, with axle diameters of between 0.5 to 1.25 inches. This gives each wheel a carrying capacity of between 700 and 15,000 pounds. This wide range makes it possible to customize a wheel capable of handling any task.

The self-cleaning V-groove makes the wheel ideal for navigating wet, debris-covered environments. Our grooves have a width of between seven-eighths and 1.75 inches, with a groove depth between seven-sixteenths and eleven-sixteenths inches. These grooves prevent clogs from forming that could topple the load and cause damage to the cargo or equipment under transport.

The wheels are comparatively light and make it possible to support heavy loads without adding extensive weight to equipment, carts, etc. When desired, it’s possible to add polyurethane tubes or inset rubber to provide additional protection for flooring and improve traction.

If you’d like to learn more about the ways our clients customize their V-groove wheels, contact RWM at 800-634-7704, and we will help you select the ideal design for your applications and work environment.

Industries & Applications

The design of V-groove wheels makes them ideal for navigating the most challenging work environments. Designed to operate in extreme temperatures, these wheels won’t break down when exposed to high or low temperatures. Sturdy design means that they facilitate efficient turns and can make travel between tight spaces with ease. Their superior load-carrying capacity means they can travel long distances without breaking down or locking up.

V-groove wheels can be used in a wide range of industrial applications. They are ideal for mechanic shops and are frequently used to move heavy industrial equipment. They are also common on office chairs and garbage containers. When desired, V-groove wheels can transport equipment and cargo over raised iron or steel tracks.

Their versatility of design means they can be used in automobile assembly, aerospace assembly, ventilation equipment manufacturing, food processing, welding, lumber processing, and more. These wheels are designed to provide reliable operation in the most challenging and demanding work environments imaginable.

If you want to to learn more about the many applications your business can use V-groove wheels, contact RWM at 800-634-7704, and our team will be happy to tell you more about these smooth-rolling, high-strength wheels.

Benefits of V-Groove Wheels by RWM Casters

If you need wheels with enhanced strength through cast iron (VI) or forged steel (VF) for applications on an inverted angle iron track, consider our premium VF and VI wheels. These wheel bearings offer straight or tapered roller bearings and can be cut or lengthened with spacers. Designed for application on an inverted track and smooth floor surfaces, our V-groove wheels are used to control the flow of a load as needed when transporting contents into an oven, between machines, or over long distances. Consider the benefits of these high-strength wheels for assembly production lines, manufacturing facilities, and other industrial applications:

Strength: Being forged from cast iron or steel allows our V-groove wheels to maintain superior strength whether operating on a track, flat surface, or both. Capable of handling between 700 to 15,000 pounds, they provide great flexibility.

Versatility: Capable of operating on an inverted track or any flat surface, RWM’s VF and VI wheels provide ample versatility and efficiency for your industry’s application.

Enhanced efficiency: Utilizing floor space effectively by operating on or off a track, our V-groove wheels allow optimal functionality in transporting heavy-duty loads.

Uses for V-Groove Wheels

Common uses for V-groove wheels throughout various applications include:

- Rolling ovens

- Automotive production line

- Aerospace assembly

- Ventilation equipment

- Sawmills on tracks or bars

Choose RWM for VF & VI Wheels

No matter which wheels, casters, or other material handling solutions you order from us, you can count on exceptional quality control and an emphasis on customer service. RWM is recognized as the market leader for industrial casters and can help you find the perfect solution for your needs. With us on your side, all your applications will be rolling smoothly in no time.

If you’re ready to place an order for delivery, or if you need additional information on V-groove wheel options and customization options, please call us at 800-634-7704 or contact RWM online!

What size V-groove wheel should I choose?

The size wheel you need depends on your application. A wheel with a higher width and diameter can bear a higher weight, but they are also heavier. If you don’t require wheels for heavy loads, you can choose a smaller wheel with less weight.

Are cast-iron or forged steel V-groove wheels better?

Cast-iron and forged steel are both great materials used in our V-groove wheels. Which one is better will depend on your applications. Our forged steel V-groove wheels (VF) have higher weight capacities, capable of handling up to 15,000 pounds, whereas cast-iron wheels (VI) can handle up to 6,000 pounds. Forged steel is also the better choice for applications with a significant risk of shock loading. An advantage of cast-iron wheels is that they are less expensive than forged steel.