65 Series Casters

Heavy-Duty Kingpinless Casters

RWM Casters is proud to be the inventor of the original Kingpinless™ casters, the best solution for demanding, high-capacity, and abusive settings. The 65 Series is a suitable option if you need casters for manufacturing, heavy-duty industrial, aerospace, or automotive applications. The Kingpinless design is simply unmatched in its ability to extend the caster’s service life and reduce the possibility of failure. Our 65 Series casters are proudly made in the USA.

Benefits of the 65 Series Kingpinless Caster

Consider the benefits of this heavy-duty caster for towing, aircraft maintenance, and other industrial applications:

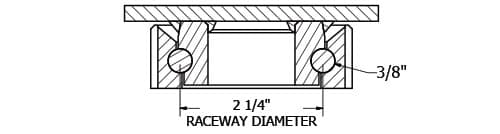

- Optimal performance and longevity: Kingpinless casters are suitable anytime you want a smooth swiveling action and exceptional maneuverability. All swivel actions come with a lubrication fitting for field maintenance. Plus, our single ball bearing, precision-machined, and case-hardened raceways ensure superior operation and a longer life span compared to copycat Kingpinless designs.

- Strength: The 65 Series is rated at up to 2,000 lbs per caster for impressive capacity when you need it. The Kingpinless raceways offer extra impact resistance and high radial force absorption. Plus, more thorough heat treatment and added mass at key points provide additional strength and combat material surface failure caused by excessive stress.

- Versatility: Available in 4-, 5-, 6-, and 8-inch sizes, you can couple the 65 Series with any two-inch-wide wheels to meet your needs. Popular options include forged steel, performance TPR, rubber on iron, and many others, depending on your specifications.

- Corrosion resistance: The frame is plated in zinc to protect against corrosion in settings where the casters may be exposed to water, steam, cleaning agents, or other corrosive chemicals.

Features

| Raceway Design | Patented Kingpinless™ single ball bearing precision-machined raceway hardened to 53 Rockwell C. minimum. Swivel section features 2-3/8” diameter raceway with 3/8” ball bearings. |

| Capacity | Up to 2000 lbs. |

| Swivel Section | All swivel sections are supplied with a lubrication fitting for field maintenance |

| Leg Thickness | 1/4” formed steel |

| Axle | 1/2” bolt and locking nut drilled with lube fitting |

| Finish | Zinc plated to protect against corrosion |

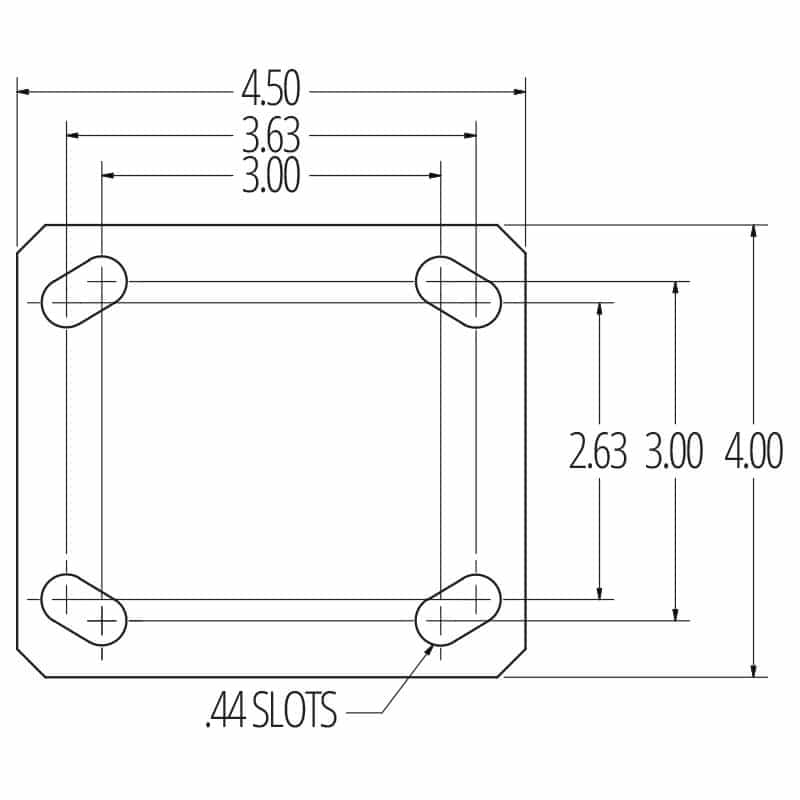

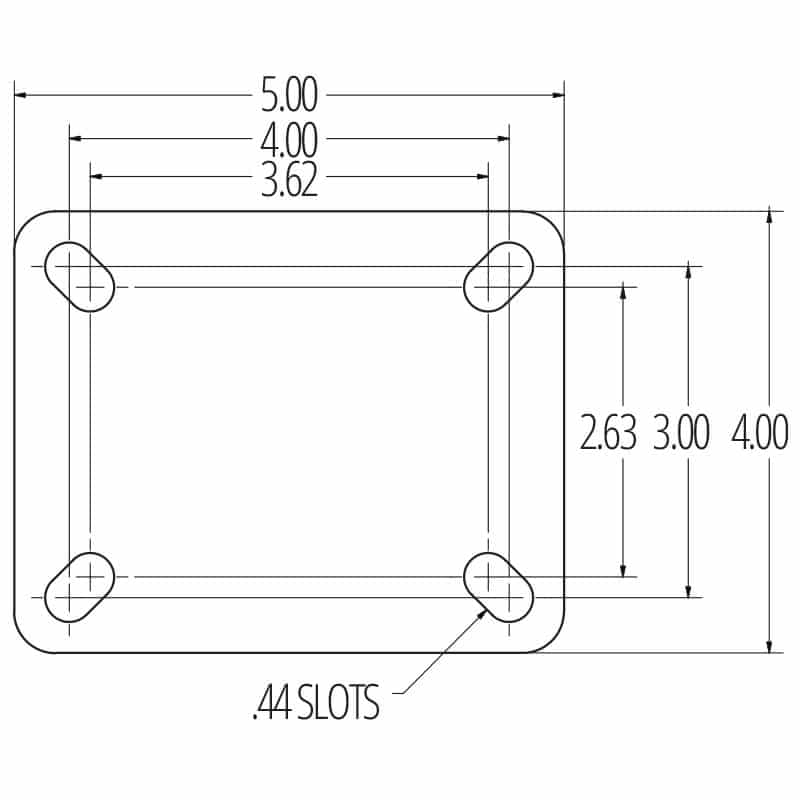

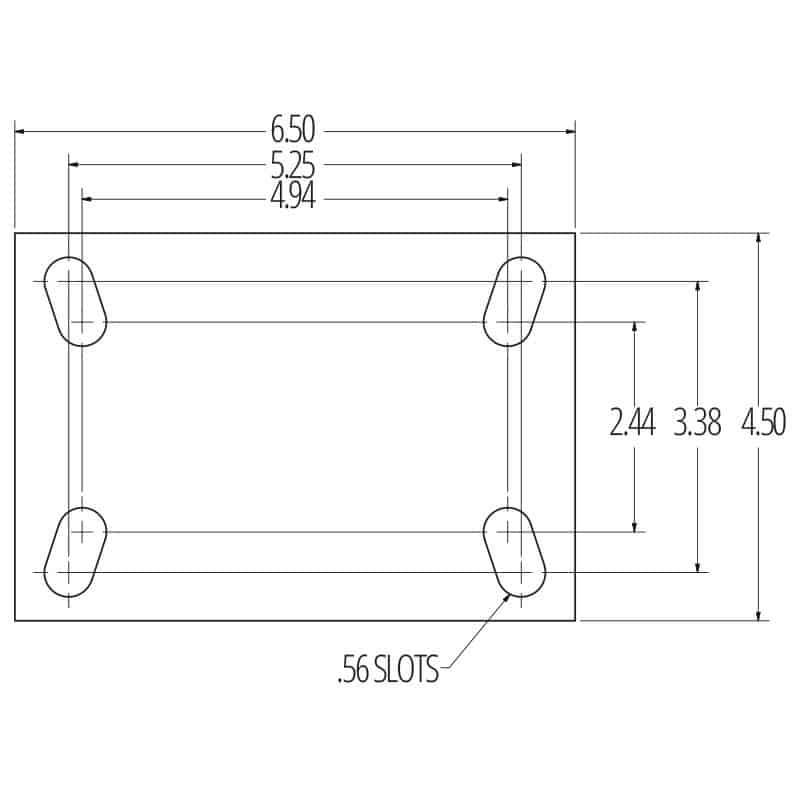

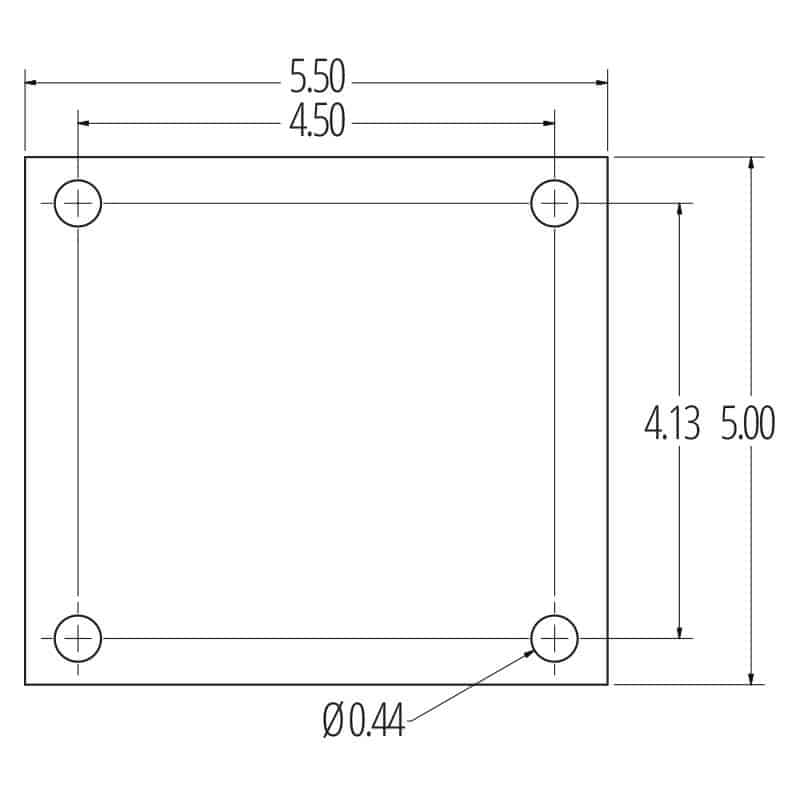

| Mounting Plate Size | 4” x 4-1/2” x 1/4” |

| Bolt Hole Spacing | 2-5/8” x 3-5/8” slotted to 3” x 3” |

| Mounting Bolt Diameter | 3/8” |

Applications

| Aircraft maintenance and support applications | Heavy duty industrial applications |

| Towing applications | Manufacturing applications |

| Automotive assembly lines |

| ICWB | Installable Face Contact Brake |

| MICWB | Metal Installable Cam Wheel Brake |

| *WB | Side Wheel Brake |

| *WWB | Wraparound Wheel Brake |

| CWB | Cam Wheel Brake |

| DSL | Demountable Swivel Lock |

| DLSL | Demountable L-Handle Lock |

| SL | Swivel Lock |

| FOSL | Foot Operated Swivel Lock |

| LP | Locking Plate-Total Lock for 8" Casters Only |

| HT | High Temperature Lubrication |

| LT | Low Temperature Lubrication |

| TG | Thread Guards |

| WS | Wheel Seals |

| FIFG | Field Installable Foot Guard |

| FG | Foot Guard |

| SR | Sealed Raceway |

| HTP | High Temperature Paint |

| WHEEL DIAMETER | WHEEL WIDTH | CAPACITY | WHEEL TYPE | OVERALL HEIGHT | ROLLER BEARING | STRAIGHT ROLLER BEARING | BALL BEARING | CELCON BEARING | SWIVEL LEAD | APPROX WEIGHT |

|---|---|---|---|---|---|---|---|---|---|---|

| 4'' | 1-1/2" | 1400 | Forged Steel | 5-5/8″ | 65-FSR-0415-S | 65-FSC-0415-S | 1-3/16″ | 9 | ||

| 4'' | 2" | 350 | Performance TPR | 5-5/8″ | 65-RPR-0420-S | 65-RPB-0420-S | 65-RPC-0420-S | 1-3/16″ | 7.3 | |

| 4'' | 2" | 350 | Rubber on Iron | 5-5/8″ | 65-RIR-0420-S | 65-RIC-0420-S | 1-3/16″ | 8 | ||

| 4'' | 2" | 400 | Signature | 5-5/8″ | 65-SWR-0420-S | 65-SWB-0420-S | 65-SWC-0420-S | 1-3/16″ | 7 | |

| 4'' | 2" | 500 | Polyolefin | 5-5/8″ | 65-POR-0420-S | 65-POB-0420-S | 65-POC-0420-S | 1-3/16″ | 7.6 | |

| 4'' | 2" | 600 | Urethane Polypropylene | 5-5/8″ | 65-UPR-0420-S | 65-UPB-0420-S | 65-UPC-0420-S | 1-3/16″ | 7.3 | |

| 4'' | 2" | 700 | Rubber on Aluminum | 5-5/8″ | 65-RAB-0420-S-EHT | 1-3/16″ | 8 | |||

| 4'' | 2" | 700 | Solid Urethane | 5-5/8″ | 65-MUB-0420-S | 1-3/16″ | 7 | |||

| 4'' | 2" | 700 | Urethane on Aluminum | 5-5/8″ | 65-UAR-0420-S | 65-UAC-0420-S | 1-3/16″ | 7.5 | ||

| 4'' | 2" | 700 | Urethane on Iron | 5-5/8″ | 65-UIR-0420-S | 65-UIC-0420-S | 1-3/16″ | 8 | ||

| 4'' | 2" | 800 | Cast Iron | 5-5/8″ | 65-CIR-0420-S | 65-CIB-0420-S | 65-CIC-0420-S | 1-3/16″ | 10 | |

| 4'' | 2" | 800 | Durastan | 5-5/8″ | 65-DUR-0420-S | 65-DUB-0420-S | 65-DUC-0420-S | 1-3/16″ | 8 | |

| 4'' | 2" | 800 | High Temp. Nylon | 5-5/8″ | 65-HNR-0420-S | 1-3/16″ | 8 | |||

| 4'' | 2" | 800 | Pinnacle | 5-5/8″ | 65-PNR-0420-S | 65-PNB-0420-S | 65-PNC-0420-S | 1-3/16″ | 8 | |

| 4'' | 2" | 800 | V-Groove Iron | 5-5/8″ | 65-VIR-0420-S | 65-VIC-0420-S | 1-3/16″ | 10 | ||

| 4'' | 2" | 1050 | GT | 5-5/8″ | 65-GTB-0420-S | 1-3/16″ | 8 | |||

| 4'' | 2" | 2000 | Nylatron HD | 5-5/8″ | 65-NYB-0420-S | 1-3/16″ | 8.5 | |||

| 5'' | 2" | 375 | Performance TPR | 6-1/2″ | 65-RPR-0520-S | 65-RPB-0520-S | 65-RPC-0620-S | 1-3/8″ | 7.3 | |

| 5'' | 2" | 400 | Rubber on Iron | 6-1/2″ | 65-RIR-0520-S | 65-RIC-0520-S | 1-3/8″ | 9 | ||

| 5'' | 2" | 500 | Signature | 6-1/2″ | 65-SWR-0520-S | 65-SWB-0520-S | 65-SWC-0520-S | 1-3/8″ | ||

| 5'' | 2" | 650 | Polyolefin | 6-1/2″ | 65-POR-0520-S | 65-POB-0520-S | 65-POC-0520-S | 1-3/8″ | ||

| 5'' | 2" | 750 | Urethane Polypropylene | 6-1/2″ | 65-UPR-0520-S | 65-UPB-0520-S | 65-UPC-0520-S | 1-3/8″ | ||

| 5'' | 2" | 800 | Rubber on Aluminum | 6-1/2″ | 65-RAB-0520-S-EHT | 1-3/8″ | ||||

| 5'' | 2" | 800 | V-Groove Iron | 6-1/2″ | 65-VIR-0520-S | 65-VIC-0520-S | 1-3/8″ | 12 | ||

| 5'' | 2" | 1000 | Cast Iron | 6-1/2″ | 65-CIR-0520-S | 65-CIB-0520-S | 65-CIC-0520-S | 1-3/8″ | 12 | |

| 5'' | 2" | 1000 | Durastan | 6-1/2″ | 65-DUR-0520-S | 65-DUB-0520-S | 65-DUC-0520-S | 1-3/8″ | 9 | |

| 5'' | 2" | 1000 | High Temp. Nylon | 6-1/2″ | 65-HNR-0520-S | 1-3/8″ | 9 | |||

| 5'' | 2" | 1000 | Pinnacle | 6-1/2″ | 65-PNR-0520-S | 65-PNB-0520-S | 65-PNC-0520-S | 1-3/8″ | 9 | |

| 5'' | 2" | 1000 | Solid Urethane | 6-1/2″ | 65-MUB-0520-S | 1-3/8″ | 7.6 | |||

| 5'' | 2" | 1050 | Urethane on Aluminum | 6-1/2″ | 65-UAR-0520-S | 65-UAC-0520-S | 1-3/8″ | |||

| 5'' | 2" | 1050 | Urethane on Iron | 6-1/2″ | 65-UIR-0520-S | 65-UIC-0520-S | 1-3/8″ | 9 | ||

| 5'' | 2" | 1200 | GT | 6-1/2″ | 65-GTB-0520-S | 1-3/8″ | 9 | |||

| 5'' | 2" | 1500 | Forged Steel | 6-1/2″ | 65-FSR-0520-S | 65-FSC-0520-S | 1-3/8″ | 12 | ||

| 5'' | 2" | 2000 | Nylatron HD | 6-1/2″ | 65-NYB-0520-S | 1-3/8″ | 9.5 | |||

| 6" | 2" | 410 | Rubber on Iron | 7-1/2″ | 65-RIR-0620-S | 65-RIC-0620-S | 1-9/16″ Optional 2-1/2″ | 10 | ||

| 6" | 2" | 525 | Performance TPR | 7-1/2″ | 65-RPR-0620-S | 65-RPB-0620-S | 65-RPC-0620-S | 1-9/16″ Optional 2-1/2″ | 7.7 | |

| 6" | 2" | 600 | Signature | 7-1/2″ | 65-SWR-0620-S | 65-SWB-0620-S | 65-SWC-0620-S | 1-9/16″ Optional 2-1/2″ | 9 | |

| 6" | 2" | 700 | Polyolefin | 7-1/2″ | 65-POR-0620-S | 65-POB-0620-S | 65-POC-0620-S | 1-9/16″ Optional 2-1/2″ | 8.7 | |

| 6" | 2" | 820 | Rubber on Aluminum | 7-1/2″ | 65-RAB-0620-S-EHT | 1-9/16″ Optional 2-1/2″ | 10 | |||

| 6" | 2" | 900 | Urethane Polypropylene | 7-1/2″ | 65-UPR-0620-S | 65-UPB-0620-S | 65-UPC-0620-S | 1-9/16″ Optional 2-1/2″ | 7.7 | |

| 6" | 2" | 1000 | Omega | 7-1/2″ | 65-UOR-0620-S | 65-UOB-0620-S | 65-UOC-0620-S | 1-9/16″ Optional 2-1/2″ | 12 | |

| 6" | 2" | 1000 | V-Groove Iron | 7-1/2″ | 65-VIR-0620-S | 65-VIC-0620-S | 1-9/16″ Optional 2-1/2″ | 13 | ||

| 6" | 2" | 1200 | Cast Iron | 7-1/2″ | 65-CIR-0620-S | 65-CIB-0620-S | 65-CIC-0620-S | 1-9/16″ Optional 2-1/2″ | 13 | |

| 6" | 2" | 1200 | Durastan | 7-1/2″ | 65-DUR-0620-S | 65-DUB-0620-S | 65-DUC-0620-S | 1-9/16″ Optional 2-1/2″ | 10 | |

| 6" | 2" | 1200 | High Temp. Nylon | 7-1/2″ | 65-HNR-0620-S | 1-9/16″ Optional 2-1/2″ | 10 | |||

| 6" | 2" | 1200 | Pinnacle | 7-1/2″ | 65-PNR-0620-S | 65-PNB-0620-S | 65-PNC-0620-S | 1-9/16″ Optional 2-1/2″ | 10 | |

| 6" | 2" | 1200 | Solid Urethane | 7-1/2″ | 65-MUB-0620-S | 1-9/16″ Optional 2-1/2″ | 9 | |||

| 6" | 2" | 1230 | Torus | 7-1/2″ | 65-UIR-0620-S | 65-UIC-0620-S | 1-9/16″ Optional 2-1/2″ | 11 | ||

| 6" | 2" | 1230 | Urethane on Aluminum | 7-1/2″ | 65-UAR-0620-S | 65-UAC-0620-S | 1-9/16″ Optional 2-1/2″ | 11 | ||

| 6" | 2" | 1230 | Urethane on Iron | 7-1/2″ | 65-UIR-0620-S | 65-UIC-0620-S | 1-9/16″ Optional 2-1/2″ | |||

| 6" | 2" | 1500 | GT | 7-1/2″ | 65-GTB-0620-S | 1-9/16″ Optional 2-1/2″ | ||||

| 6" | 2" | 1800 | Forged Steel | 7-1/2″ | 65-FSR-0620-S | 65-FSC-0620-S | 1-9/16″ Optional 2-1/2″ | |||

| 6" | 2" | 2000 | Nylatron HD | 7-1/2″ | 65-NYB-0620-S | 1-9/16″ Optional 2-1/2″ | ||||

| 8" | 2" | 500 | Rubber on Iron | 10-1/8″ | 65-RIR-0820-S | 65-RIC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 11 | ||

| 8" | 2" | 600 | Performance TPR | 10-1/8″ | 65-RPR-0820-S | 65-RPB-0820-S | 65-RPC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 9.1 | |

| 8" | 2" | 700 | Signature | 10-1/8″ | 65-SWR-0820-S | 65-SWB-0820-S | 65-SWC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 10 | |

| 8" | 2" | 800 | Polyolefin | 10-1/8″ | 65-POR-0820-S | 65-POB-0820-S | 65-POC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 9.1 | |

| 8" | 2" | 1000 | Rubber on Aluminum | 10-1/8″ | 65-RAB-0820-S-EHT | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 11 | |||

| 8" | 2" | 1000 | Urethane Polypropylene | 10-1/8″ | 65-UPR-0820-S | 65-UPB-0820-S | 65-UPC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 9.1 | |

| 8" | 2" | 1050 | Torus | 10-1/8″ | 65-VIR-0820-S | 65-VIC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 16 | ||

| 8" | 2" | 1200 | Omega | 10-1/8″ | 65-UOR-0820-S | 65-UOB-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 13 | ||

| 8" | 2" | 1400 | Cast Iron | 10-1/8″ | 65-CIR-0820-S | 65-CIB-0820-S | 65-CIC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 16 | |

| 8" | 2" | 1400 | Durastan | 10-1/8″ | 65-DUR-0820-S | 65-DUB-0820-S | 65-DUC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 11 | |

| 8" | 2" | 1400 | Pinnacle | 10-1/8″ | 65-PNR-0820-S | 65-PNB-0820-S | 65-PNC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 11 | |

| 8" | 2" | 1500 | Solid Urethane | 10-1/8″ | 65-MUB-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 10 | |||

| 8" | 2" | 1500 | Torus | 10-1/8″ | 65-UAB-0821-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 12 | |||

| 8" | 2" | 1500 | Urethane on Aluminum | 10-1/8″ | 65-UAR-0820-S | 65-UAC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 12 | ||

| 8" | 2" | 1500 | Urethane on Iron | 10-1/8″ | 65-UIR-0820-S | 65-UIC-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 13 | ||

| 8" | 2" | 1800 | GT | 10-1/8″ | 65-GTB-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 11 | |||

| 8" | 2" | 2000 | Nylatron HD | 10-1/8″ | 65-NYB-0820-S | 2 -1/4″ Optional 2-1/2″ & 3-1/2″ | 12 |

Uses for 65 Series Casters

It’s essential to select the proper caster for the job at hand. Without the right features, your casters may be damaged under excessive weight, lack important safety features, or fail to function as intended. To make sure these scenarios don’t occur, we recommend working closely with RWM on your caster and wheel purchase, especially when placing your first order.

The 65 Series is one of our most popular Kingpinless casters. We recommend them for a wide range of medium- to heavy-duty applications, including:

- Automotive towlines

- Assembly lines

- Luggage distribution

- Aircraft construction

- Aerospace maintenance and repairs

If our standard product line doesn’t meet your specifications, consider a custom solution. RWM offers a computer-aided design (CAD) tool that allows you to download and receive CAD files for 65 Series casters configured for your specific application. The configurator is free to use, and the designs you create are available for immediate download.

Choose RWM for 65 Series Kingpinless Casters

Since 1935, RWM has been engineering casters to outperform the competition. Our patented Kingpinless design dates back to the 1970s, and we have continued to provide our customers with innovative solutions to this day. The 65 Series is merely one example of this.

No matter which wheels, casters, or other material handling solutions you order from us, you can count on exceptional quality control and an emphasis on customer service. We are recognized as the market leader for industrial casters and can help you find the perfect solution for your needs.

For additional caster and wheel options, application insights, and customization options, please contact RWM today at 800-634-7704.