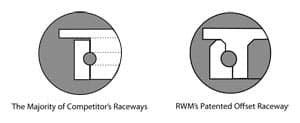

RWM Casters patented offset precision machined raceway exerts radial force evenly where there is full contact between the ball bearing and the raceway. Our unique industrial caster design adds more mass at key points. This, plus more thorough heat treatment, provides additional strength and combats brinelling into the core material.

The result:

- No direct “hammering” forces on the intersections of the raceways

- Vastly reduced raceway wear

- Elimination of the “pull apart” forces of stress in the swivel section

- Smoother swiveling action

- High maneuverability

- Longer service life

- Less maintenance

- Extra impact resistance

- High radial force absorption

The Majority of Competitor’s Raceways

The inline positioning of the competition’s raceway (as opposed to the offset positioning

utilized by RWM) creates a direct “hammering” effect via the ball bearings which are centered on the tangent of the two raceways, thus savaging and eventually eroding the raceway. The inevitable result is a loose fit and progressive swivel failure. Even a double raceway configuration is subject to these same “hammering” hazards.

The machining requirements of the competition to accommodate a swivel lock reduces strength, leading to premature fatigue, stress fractures of the raceway and eventual failure.

More Reasons to Buy RWM Kingpinless™ Casters

No caster shimmy. Superior strength means superior performance – and RWM’s patented swivel section provides the strength to build longer swivel leads that function flawlessly – even at high speeds – without shimmy. We have applied over 100,000 pounds of impact forces to our 125 series with a 5″ swivel lead with no damage to the swivel section.

Closer machine tolerances. RWM swivel section tolerances are .017, compared with .030 for the competition. This differential represents the amount of play between the top plate and the swivel yoke. The more

precise the machining, the closer the tolerances; and the closer the

tolerances, the longer the service life.

Double-welded construction. RWM’s raceway provides the additional mass necessary for a double weld on its legs, inside and outside, as opposed to the competition’s single weld.

Their machining process does not provide the necessary mass for

a weld on the outside race.

Higher carbon steel. Tests prove that RWM legs have a 74% higher yield strength* than the competition, and a 74% higher ultimate strength** than the competition. RWM’s carbon content, the essential ingredient for strength in steel, is nearly seven times higher than the competition.

Superior heat treatment. The steel in RWM’s race is superior in its heat treatment – nearly 18% harder than the competition. As a result, the RWM welded-in race is nearly 20% better equipped to resist brinelling that the competition, and allows the swivel section to turn

easily in the roughest applications.

*The point at which steel begins to stretch like a rubber band

**The point at which steel actually snaps in two pieces