RWM Casters understands that not all products are standard catalog items. For over 75 years of industrial caster and wheel production, we have developed a catalog of our primary caster, wheel, and material handling products. However, behind the scenes are thousands of custom-designed industrial caster and wheel products and configurations designed specifically for our individual customer’s needs. If you have a custom industrial caster and wheel application or material handling product need, we will happily assist in the design, prototyping, and production of your “dream” product and get you rolling in no time!

If you’re ready to get started working with RWM for your ICWM wheel and caster production, among other things, call 800-634-7704 now.

MANUFACTURING

- In-house tool & die shop

- CNC turning centers up to 20″

- Fully automated high-density plasma cutting tables

- Fusion Arc 2 cell robotic weld center

- Fusion Arc 2 cell robotic weld center with tailstock

- Fusion Arc 3 cell robotic weld center with tailstock

- Fusion Arc 4 cell robotic weld center

- Lincoln and Miller MIG welders

- Stamping and forming presses

- Engine lathes

- Milling and grinding centers

- Heat treatment

- Vibratory and blast finishing

- Hot rinse part preparation

- Spray booth and dipping stations

- Powder coating

- Electropolishing line for stainless steel

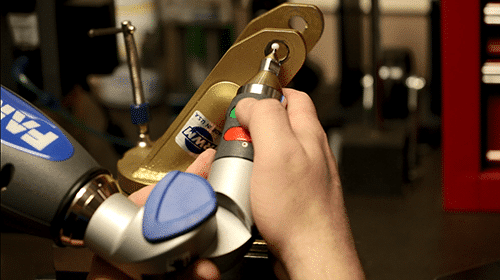

QUALITY CONTROL AND TESTING

RWM has a dedicated staff of quality-oriented personnel striving to meet the highest of quality standards. Our in-house testing facility allows us to perform the necessary testing to keep existing products top notch and make future products even better.

- ISO 9001 registered

- ICWM member company

- RWM quality standards meet or exceed that of ICWM

- Heavy-duty hydraulic drum testing machine up to 12mph

- Variable high-speed drum test machine

- Cart push/pull testing

- C.F.T.M.A. durability testing

- Shock absorber height and rebound testing

- Static load testing

- Wheel tread adhesion test

- Brake engagement & holding power

- Impact and shock load testing

- Material hardness

- Chemical composition analysis

- Metallographic examination

- Faro Gage 3-D Inspection CMM

- ICWM caster production

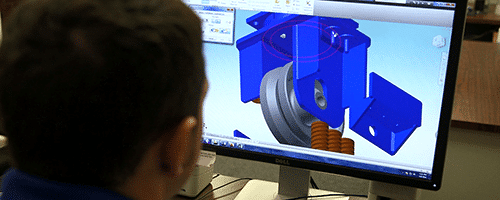

ENGINEERING

At RWM Casters, our engineers aspire to conceptualize, design, and construct the most innovative and technologically superior industrial caster and wheel products known to the material handling industry. Our catalog of over 70,000 material handling products continues to grow every day; however, custom design and fabrication is still a mainstay of the RWM Casters mentality. If you don’t see it, chances are we can still fulfill all your non-powered material handling needs!

- Autodesk Inventor Simulation Suite

- FEA capabilities

- Design & prototype

- Complete 3-D modeling & website 3-D integration

- AutoCad and 2-D possibilities

- ISO standards & procedures

- 3-D printer

- Click to view a sampling of our custom manufactured products