Time is money, and the team at RWM Casters uses the latest technologies to reduce the time it takes to create your projects so that you can make more money. It’s a simple equation that we apply for our clients in a broad range of industries, including automotive manufacturing textile production, aerospace engineering, tire manufacturing, and more. When you need precision, you can depend on our computer-aided design tools to help ensure your custom order is delivered promptly and accurately.

When you need top-quality CAD services, the team at RWM Casters is ready to help. Contact our team today get a quote and get started on your projects.

Free CAD Downloads

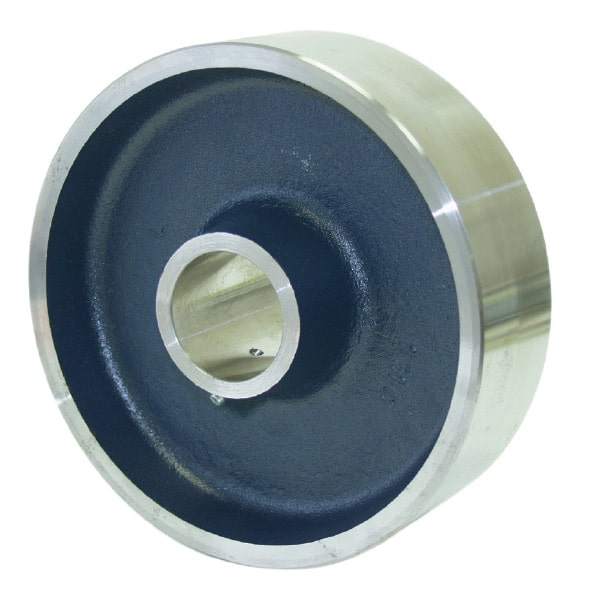

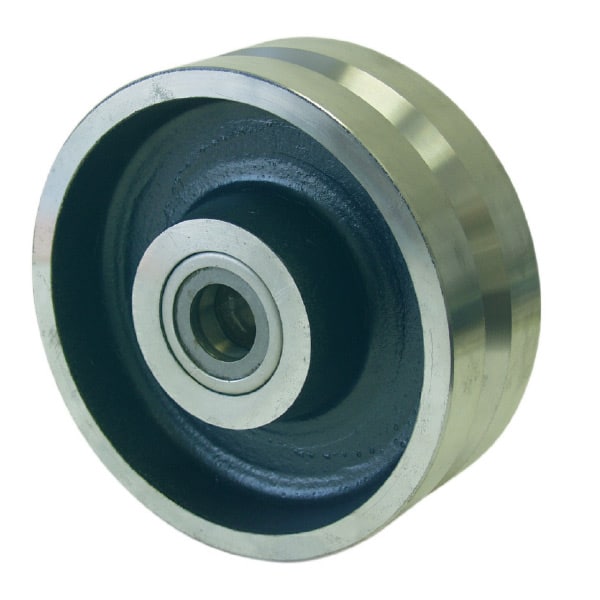

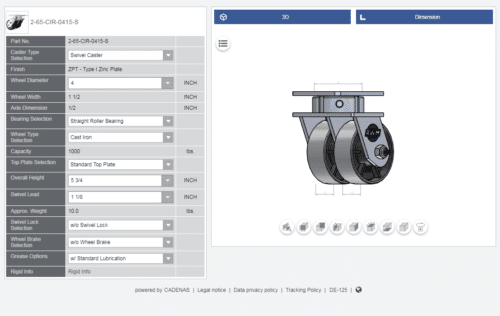

Our clients can access our CAD files directly through our website. We maintain a database of more than 600,000 CAD combinations that can be customized to meet your needs. Simply download our CAD downloader and create an account and profile. Next, you can use the filter system to determine the optimal caster or wheel series you want to customize. This will pull up a 3D rendering of the caster or wheel that you can download and alter to meet your requirements. You can change a broad range of product specifications and parameters so that the finished product will provide superior performance within the intended operating environment.

When the design is complete, you can send the file to our design and engineering teams, who will then begin the process of creating the casters or wheels you need for your business. It’s fast and simple, and it allows you to receive the customized solutions you need quickly, efficiently, and for a lower cost than our competitors.

Benefits of CAD Files

There are plenty of benefits that you’ll enjoy by using CAD files with RWM Casters, including:

- Saves time: Time is your most valuable resource and CAD files expedite the design process.

- Reduces errors: CAD files ensure the finished product meets the highest quality standards. Moreover, the design process itself allows designers to see and correct design deficiencies to create a superior-quality product.

- Customization: CAD files make it easy to customize casters and wheels. This includes exploring a broad range of configurations, materials, braking systems, and other elements.

- Fast collaboration: CAD files are easily shared with members of your team and the team at RWM. This allows for rapid adjustments and makes it possible for multiple individuals to examine the design and provide input at every stage of the process.

- Ties in with Computer-Aided Manufacturing (CAM): CAM helps ensure precision manufacturing, and RWM uses these technologies to read your CAD files and bring your designs to life quickly and efficiently.

Why Choose Us?

At RWM Casters, our customer service personnel, engineers, designers, and manufacturing teams work together as a single unit whose goal is to ensure you receive the superior products and precision manufactured solutions you need. Our American-made products set industry standards for quality, price, and lead times. When you want innovations second to none, then the team at RWM is ready and willing to bring your visions to life.

Contact RWM Casters to learn more about our CAD services and to place a custom order today!

Frequently Asked Questions

Are there any disadvantages to CAD?

Sudden work loss due to computer failure, computer viruses, and hacking are all potential hazards when using CAD files. For these reasons, we strongly recommend making backups of your designs, only allowing access via secure computers, and limiting the number of people who have access to your designs.

How challenging is it to create a CAD file?

It’s not hard at all. While there is a slight learning curve to the process, our team will guide you through every step to ensure the finished product is precisely the solution you need.

Can RWM help calculate capacity based on the adjustments we make with our CAD files?

Our team can help you calculate the impact of a wide range of changes to wheel width, size, material, etc. We can also make recommendations that will ensure your wheel delivers the performance required for your intended applications, working environment, and other factors.