When every millimeter counts, there is no substitute for precision movement. Whether you need a turntable for a product display, a dolly, or a welding table, RWM Casters’ turntable swivel sections are designed to provide smooth, efficient, and reliable 360-degree rotation. We manufacture solid turntable swivel sections that exceed your expectations at every turn and on every task.

Kingpinless Design Creates Robust and Efficient Rotation

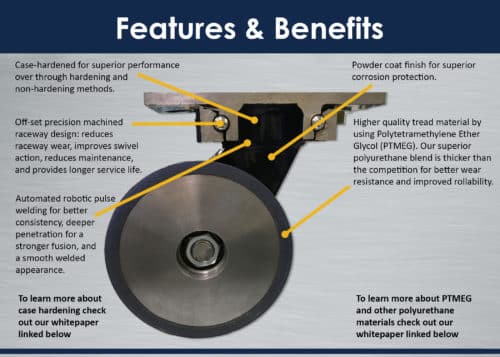

Our patented Kingpinless swivel design ensures that the turntable delivers maximum productivity with minimal wear and tear on components. To that end, our swivel sections are built around a single ball bearing set with a precision-machined raceway. Once hardened to a 53 Rockwell C, each swivel section that rolls off our production line will deliver smooth turns and superior carrying capacity for loads ranging from 900 to 30,000 pounds. Whether you are moving a welding table or turning a vehicle around, you will have no trouble safely making the maneuver with our Kingpinless swivel design.

Durable, Dependable, and Always Down To Work

It may be hard to find good help, but it’s never hard to find reliable equipment you can depend on. RWM’s turntable swivel sections are easy to maintain and feature an easy-to-reach lubrication fitting that allows you to lubricate the motion at any time and under any conditions. During our design and testing process, we put our turntable swivel sections through grueling tests to ensure they meet the highest quality standards.

The result is a finished product that we know will provide smooth operation and exceptional reliability as the years go by. Year after year, you can depend on our turntable swivel sections to show up to work and get down to business no matter how hard the work or how demanding the conditions of your work environment. From factory floors and paint booths to retail showrooms and industrial facilities, our turntables are always capable of getting the job done.

Customization Is Key

The best way to get the most out of your turntable swivel section is to customize it for your specific needs. At RWM, we offer numerous customization options that allow you to design a custom-built component equipped with the most useful features for your operations. This includes stems, center holes, and tapped-hole mounting options. We can affix regular, demountable, and L-type swivel locks to ensure the cargo, equipment, or workpiece stays right where you want it.

We can also produce sealed, greased-for-life precision bearings. This allows for maintenance-free operation, which can be a significant benefit for many businesses and types of applications. Coupled with a stainless-steel finish, zinc plating, or high-temperature paint, you will be able to expose the turntable to water, chemicals, and other hazards inherent to your work environment without ever having to worry about the component’s performance or reliability.

Further, we offer turntable swivel sections in a wide range of sizes ranging from 1/16 inches to 3/16 inches with a top plate of 4 inches by 4.5 inches to 2 7/8 inches with a top plate of 8.5 inches by 8.5 inches. This allows you to choose a component that is perfectly sized for your needs. Our smallest sections can carry up to 900 pounds, while our larger, 2/12-inch sections can carry up to 10,000, and even up to 30,000 pounds for the 2 7/8″ option.

Contact RWM Casters at 800-634-7704 to learn more about our turntable swivel sections.