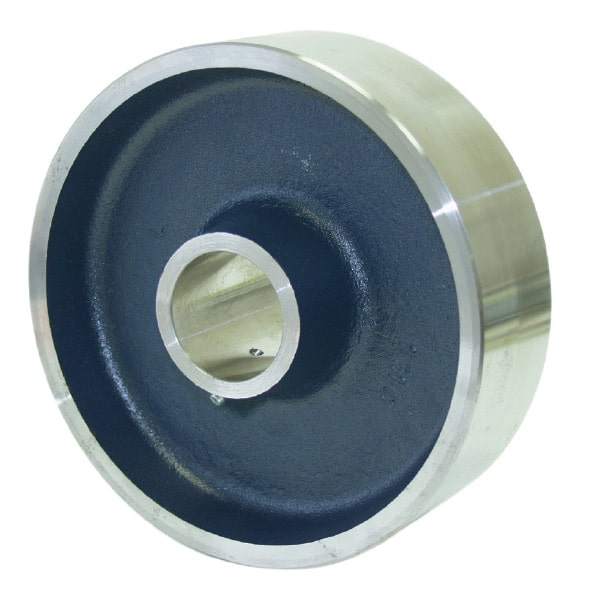

Forged Steel Wheels

FS Wheels

If you need a wheel that’s virtually indestructible, RWM’s forged steel wheels are the product for you. With uncompromising strength and extreme load-bearing capacity, our forged steel wheels are designed for use in the most demanding of applications. These wheels feature a weight capacity of up to 20,000 pounds and can be used in high-temperature applications up to 800 degrees F.

Find out what makes RWM’s products the best by calling us at 800-634-7704 or contacting us online for a quote on forged steel wheels.

Features

| Wheel Bearings | Choice of straight roller bearings or precision tapered bearings |

| Temperature Range | -50 degrees to 800 degrees F |

| Hub Length | Can be shortened or lengthened to order |

| Lubrication Fittings | Standard on 2.5 inches and wider wheels |

| Bores | Sizes can be altered |

| Keyways | Can be installed on most sizes |

Applications

In short, forged steel is appropriate for any rigorous, high-capacity application. The incredible strength-to-weight ratio of these caster wheels means they can handle incredible payload capacities. This makes them suitable for bearing the weight of various kinds of industrial equipment. Examples of applications where forged steel wheels could be ideal include:

|

| SI | Spanner Includes |

| TG | Thread Guard on 1-1/2″ and 2″ tread wheels |

| WS | Wheel Seals |

| ZF | Zerk Fittings |

| WHEEL DIAMETER | WHEEL WIDTH | CAPACITY | WHEEL TYPE | AXLE DIAMETER | STRAIGHT ROLLER BEARING | TAPERED BEARING | HUB LENGTH | APPROX WEIGHT |

|---|---|---|---|---|---|---|---|---|

| 4'' | 1-1/2" | 1400 | 1-1/2″ | FSR-0415-08 | 2-7/16″ | 3.1 | ||

| 4'' | 1-1/2" | 1400 | 5/8″ | FSR-0415-10 | 2-7/16″ | 3.1 | ||

| 4'' | 1-1/2" | 1400 | 3/4″ | FSR-0415-12 | 2-7/16″ | 3.1 | ||

| 5'' | 2" | 1500 | 1/2″ | FSR-0520-08 | FST-0520-08 | 2-7/16″ | 5 | |

| 5'' | 2" | 1500 | 5/8″ | FSR-0520-10 | 2-7/16″ | 5 | ||

| 5'' | 2" | 1500 | 3/4″ | FSR-0520-12 | 2-7/16″ | 5 | ||

| 6" | 2" | 1800 | 1/2″ | FSR-0620-08 | FST-0620-08 | 2-7/16″ | 6.3 | |

| 6" | 2" | 1800 | 5/8″ | FSR-0620-10 | 2-7/16″ | 6.3 | ||

| 6" | 2" | 1800 | 3/4″ | FSR-0620-12 | 2-7/16″ | 6.3 | ||

| 6" | 2-1/2'' | 5000 | 3/4″ | FSR-0625-12 | FST-0625-12 | 3-1/2″ | 11.2 | |

| 6" | 2-1/2'' | 5000 | 1″ | FSR-0625-16 | FST-0625-16 | 3-1/2″ | 11.2 | |

| 6" | 3" | 7000 | 3/4″ | FSR-0630-12-SI | FST-0630-12 | 3-1/2″ | 20 | |

| 6" | 3" | 7000 | 1″ | FSR-0630-16-SI | FST-0630-16 | 3-1/2″ | 20 | |

| 6" | 3" | 7000 | 1-1/4″ | FSR-0630-20 | FST-0630-20 | 3-1/2″ | 20 | |

| 6" | 3" | 10000 | 1-1/4″ | FST-0630-20-HD | 3-1/2″ | 20 | ||

| 8" | 2-1/2'' | 4500 | 3/4″ | FSR-0825-12 | FST-0825-12 | 3-1/2″ | 18 | |

| 8" | 2-1/2'' | 4500 | 1″ | FSR-0825-16 | 3-1/2″ | 18 | ||

| 8" | 2-1/2'' | 4500 | 1″ | FSR-0825-16-SI | FST-0825-16 | 3-1/2″ | 18 | |

| 8" | 2-1/2'' | 4500 | 1-1/4″ | FSR-0825-20 | 3-1/2″ | 18 | ||

| 8" | 3" | 5500 | 3/4″ | FSR-0830-12 | FST-0830-12 | 3-1/2″ | 19 | |

| 8" | 3" | 5500 | 1″ | FSR-0830-16 | 3-1/2″ | 19 | ||

| 8" | 3" | 5500 | 1″ | FSR-0830-16-SI | FST-0830-16 | 3-1/2″ | 19 | |

| 8" | 3" | 5500 | 1-1/4″ | FSR-0830-20 | 3-1/2″ | 19 | ||

| 8" | 3" | 10000 | 1″ | FST-0830-16-HD | 3-1/2″ | 19 | ||

| 8" | 3" | 10000 | 1-1/4″ | FST-0830-20-HD | 3-1/2″ | 19 | ||

| 8" | 4" | 10000 | 1-1/4″ | FSR-0840-20 | 4-1/2″ | 36 | ||

| 8" | 4" | 10000 | 1-1/2″ | FSR-0840-24 | 4-1/2″ | 36 | ||

| 8" | 4" | 10000 | 2″ | FSR-0840-32 | 4-1/2″ | 36 | ||

| 8" | 4" | 20000 | 1-1/4″ | FST-0840-20 | 4-1/2″ | 36 | ||

| 8" | 4" | 20000 | 1-1/2″ | FST-0840-24 | 4-1/2″ | 36 | ||

| 10" | 3" | 6000 | 3/4″ | FSR-1030-12 | FST-1030-12 | 3-1/2″ | 37 | |

| 10" | 3" | 6000 | 1″ | FSR-1030-16 | 3-1/2″ | 37 | ||

| 10" | 3" | 6000 | 1″ | FSR-1030-16-SI | FST-1030-16 | 3-1/2″ | 37 | |

| 10" | 3" | 6000 | 1-1/4″ | FSR-1030-20 | FST-1030-20 | 3-1/2″ | 37 | |

| 10" | 4" | 10000 | 1-1/4″ | FSR-1040-20 | 4-1/2″ | 48 | ||

| 10" | 4" | 10000 | 1-1/2″ | FSR-1040-24 | 4-1/2″ | 48 | ||

| 10" | 4" | 10000 | 2″ | FSR-1040-32 | 4-1/2″ | 48 | ||

| 10" | 4" | 20000 | 1-1/4″ | FST-1040-20 | 4-1/2″ | 48 | ||

| 10" | 4" | 20000 | 1-1/2″ | FST-1040-24 | 4-1/2″ | 48 |

Frequently Asked Questions

What’s the difference between forged steel wheels and cast-iron wheels?

If you’re not intimately familiar with different kinds of industrial wheels, you might confuse forged steel with cast iron. However, these products have significant differences that could make one the ideal choice over the other.

Forged steel is manufactured in a hot forging operation. This involves heating medium carbon steel billets to 2,400 degrees F, or about 200 degrees below the melting point of steel. Then, the red-hot metal is hit with high-tonnage forging hammers to enhance the grain structure and increase the tensile strength of the wheel. Precision machining then completes the product with rounded edges to finished tolerances.

Cast iron is manufactured in a melting process in which scrap iron and steel are melted in a blast furnace or induction oven. The material is completely liquefied and poured into a mold. The wheel is brought to its final shape during the cooling process. Unfortunately, melting metal rather than forging it results in a significant reduction in strength compared to the virgin material.

The complex process required to manufacture forged steel makes it about 30% to 50% more expensive, but it’s also about twice as strong, offering a 20,000-pound capacity, compared to cast iron’s 10,000 pounds. Forged steel can withstand impacts as well, while cast iron is prone to cracking under such conditions.

Can forged steel wheels be customized for my applications?

Every application is different, so customization is key to getting the ideal product. At RWM Casters, we offer plenty of customizable features so that your forged steel wheels can be fitted to your specific needs. If you still can’t find what you’re looking for, give our team a call to discuss customization options.

My floors are in poor condition — can I use forged steel wheels on them?

When it comes to transporting loads across rough floors smoothly and safely, steel wheels are the ideal choice. Forged steel wheels can withstand the most abusive applications, so they can be used on floors even in the poorest conditions.

Choose RWM Casters for Heavy-Duty Forged Steel Wheels

Our goal is to help our customers select the perfect wheels and casters for the job. Our dedication to manufacturing the most exceptional products available anywhere means you never have to worry about subpar quality when you order from us. After all, we’re the original inventor of Kingpinless casters, the product by which all copycats are measured. Don’t settle for inferior knockoffs — choose RWM for the durability and longevity you expect!

We recognize that ordering the correct wheel for your application is crucial to minimize downtime, maintenance, and replacement costs. Check out the specifications of our in-stock forged steel casters. If you don’t see exactly what you’re looking for, no problem — we can custom design your wheels to whatever specs you need, including diameter, width, bore size, and more.

RWM is your source for heavy-duty forged steel rims, casters, and wheels of all shapes and sizes, so contact us today at 800-634-7704 to ask your questions or place an order!