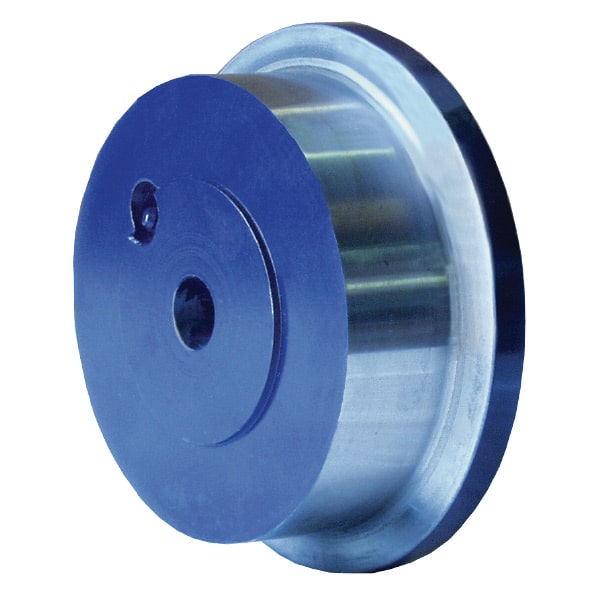

Machined Steel Flanged Wheels

FF Wheels

Our popular steel-flanged industrial wheels maneuver smoothly and evenly to avoid floor damage in commercial applications. The flange, the projecting rim that runs around the wheel’s circumference, minimizes the need for exterior guidance and reduces rolling effort.

Features

| Temperature Range | -50° to 800° F |

| Finish | Painted |

| Bores | Special sizes available upon request |

| Keyways | Can be installed on most sizes |

| Bearings | Sealed Precision Ball Bearings |

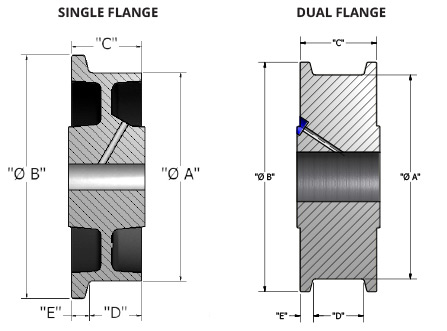

| Single Flange | “S” after bearing # |

| Dual Flange | “D” after bearing # |

| Hub Length | Includes spanner & roller bearings installed |

Applications

| Heavy-duty commercial carts | Chemical industry |

| Material transfer vehicles | Petrochemical industry |

| Foundry cooling lines | Marine industry |

| Captive turntables | Offshore loading |

| Mining operations | Pipeline engineering |

| Aerospace industry | Mechanical engineering |

| Forestry industry | Plant engineering |

| Hydropower industry | Wastewater management |

| Oil and gas industry | Food processing |

| WS | Wheel Seals |

| CAPACITY |

|---|

Benefits of Industrial Track Wheels From RWM Casters

Crucial features of flanged steel wheels include:

Innovative design of the single-flange rail wheels and track rollers protects your production floor by using integrated tracks. The cart’s wheels roll down the tracks rather than touching the floor.

Special manufacturing techniques help the wheels and steel caster assemblies to withstand the challenges of a variety of industrial applications, and our flanged steel wheels are further strengthened with heat induction. This process maximizes the service life of your wheels and increases the amount of heavy work they can do for you.

Multiple available wheel and bore sizes offer you maximum versatility and can be keyways if necessary. You can choose wheel and axle diameter options tailored to your intended application. We also stock materials handling equipment and components for your needs.

Industrial track wheels with highly capable rigs. Installed in properly sized caster rigs, the industrial steel flanged wheels support the heaviest possible loads, maxing out at a hefty 20,000 pounds.

Additional configurations like double-flanged wheels and flat-faced steel wheels are in stock to suit your needs. Handle heavy loads with ease with machined steel wheels from RWM Casters.

Call 800-634-7704 to discuss your needs or contact the RWM Casters online.

Made in the USA

At RWM Casters, we pride ourselves on making products here in the United States. Our machined steel-flanged wheels are one of our U.S.-made products, and it shows. These wheels are made to the highest standards, and their quality is unmatched.

Single- vs. Dual-Flanged Wheels

The difference between single- and dual-flanged wheels is essentially what it sounds like. Single-flanged wheels have just one flange on only one side of their tread, whereas dual-flanged wheels will have more than one. While that’s the difference at the core, it’s important to know which type is appropriate for which applications. Dual-flanged wheels are necessary when there are special safety concerns and conditions are less controlled. The flange on either side of the wheel helps to ensure they stay on track.

Not sure if you need a single- or dual-flanged wheel? Call RWM at 800-634-7704 to discuss your wheel applications.

RWM Casters Delivers the Wheels Your Industry Needs

Commercial clients can count on our reliable, precisely machined steel wheels to carry the necessary weight and never wear a path across your floor, discolor the floor, or mar its surface in any way.

Keep your loads on track the easy way, using machined steel flanged wheels from RWM!

Frequently Asked Questions

What is the weight capacity of steel flanged wheels?

RWM’s machined steel flanged wheels have exceptionally high weight-bearing capacities. Depending on their specifications, our single-flange wheels can support between 3,000 pounds to 20,000 pounds, while our dual-flanged wheels can have a capacity of between 10,000 pounds to 20,000 pounds.

Which size machined steel-flanged wheel should I get?

The size wheel you should get depends on what you need for your applications. Larger wheel diameters contribute to a heavier wheel, but they also have a higher weight capacity. If you need heavy-load bearing abilities, go with a larger wheel, but for smaller loads, a smaller wheel will be better to avoid adding extra weight.

When should I use a steel-flanged wheel?

The flanged design of these wheels is intended for use with integrated tracks. This protects your floor and also offers enhanced control over the movement of your cart, making these wheels ideal for applications where you need to minimize exterior guidance.