Even the sturdiest casters will fail over time. Whether your casters are old and worn out or simply need to be removed for repairs and servicing, it can be a challenge to remove them from assembly lines, hand trucks, carts, furniture, etc. At RWM, we understand the challenges of removing stubborn casters and dealing with stuck furniture casters. When figuring out how to remove casters, it’s imperative to move slowly and carefully lest you cause damage that can’t be repaired.

When you need top-quality casters you can rely on, contact the professionals at RWM Casters to place an order for the customized caster solutions you need to keep your business moving forward.

Rust and Corrosion

Rust and corrosion are inherent hazards to many operating environments. From loading docks and warehouses to kitchens and assembly lines, rust and corrosion can impede caster operation and make it very difficult to remove the caster for caster maintenance or replacement. It’s a very common caster removal issue. As the rust grows, it can accelerate the decline of the caster until it simply won’t roll at all. Thus, when you detect rust it’s something you should address right away. To remove rusted or corroded casters, it can help to soak the components in vinegar so the acid can break down the buildup.

Stuck or Seized Casters

Casters can seize or get stuck for a number of reasons. One of the most common is overloading the cart, hand truck, etc. This can cause components to break, which prevents the caster from rolling. Another common cause is debris that gets stuck between the wheel and the cart or lodged between various components. This debris can severely limit the caster’s range of motion, which, in turn, makes the equipment unstable and can cause it to topple when too much force is applied.

Incorrect Tools

It can be tempting to use the wrong tool simply for the sake of expediency. However, using the wrong tool when trying to remove a caster can cause extensive damage to components. Screws can strip, fittings and bolts can snap, and other issues can occur. In some cases, you may find you don’t have the right tool for the task. When this happens, it’s vital to either purchase the right tool for caster removal before attempting the job or send the item out to a professional for them to remove.

Limited Space

It would be nice to always have ample space when trying to remove a caster, but the reality is that many casters are installed in tight spaces that are difficult to reach. In some instances, you may find that you need to disassemble more than just the caster to safely remove and replace it. In these cases, it’s almost always best to take the time to create the required space rather than trying to complete the task in a confined space where you can’t effectively remove the caster or install the new one with sufficient force to ensure a secure fit.

Hidden Fasteners

Some casters are engineered to incorporate concealed fasteners for safety, functional, or aesthetic reasons. Whatever the reason, it’s not uncommon for casters to have a hidden fastener that you’ll need to locate to remove the caster. If you’re unsure whether your caster has a hidden fastener, it’s always best to consult information about the specific model and design before attempting service.

Depend on RWM Casters for Your Caster Needs

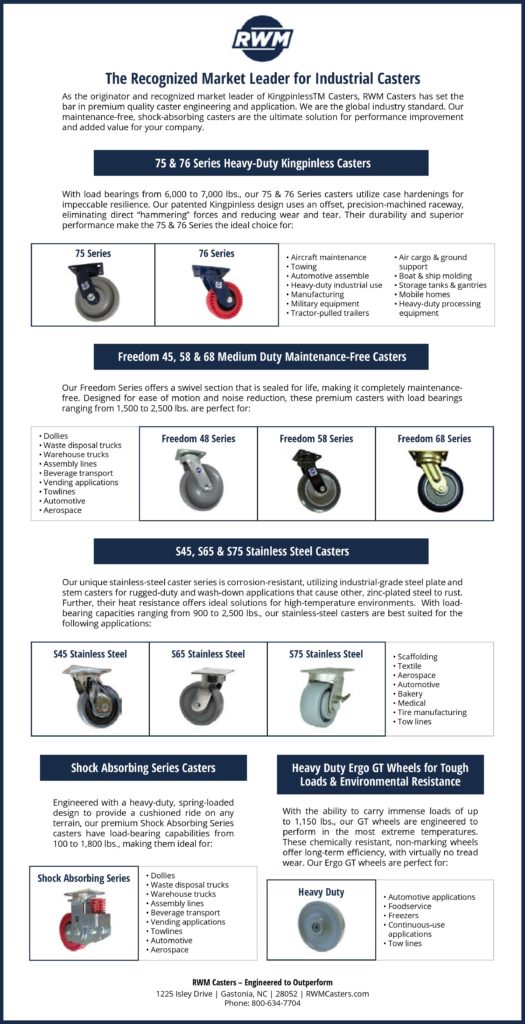

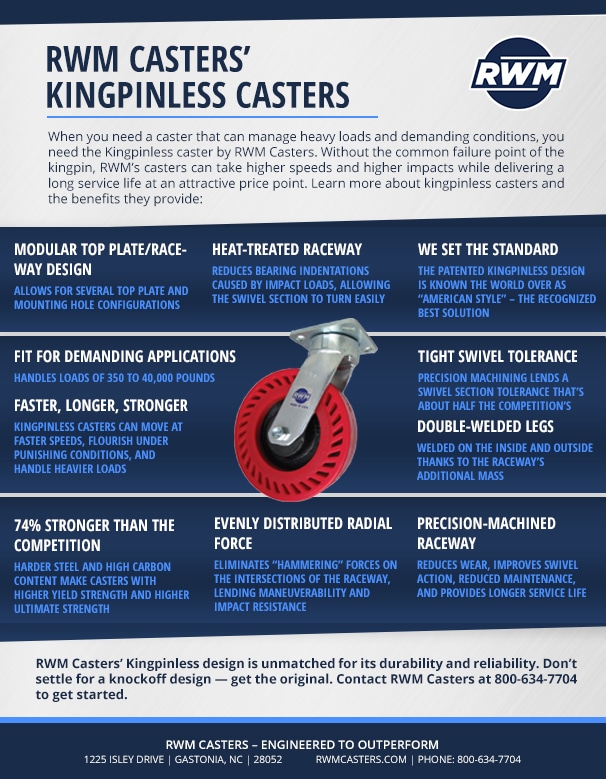

At RWM, we are the world’s recognized market leader in kingpinless casters. When you choose our team, you can rest assured our solutions are engineered to outperform the competition. Our American-made products are manufactured to the highest quality standards, and we guarantee your satisfaction with the durability, performance, and custom features we offer. When you want competitive prices and industry-best lead times, we’re ready to show you why our innovative solutions are the solutions you need to achieve the goals you set for your business.

At RWM, we manufacture the world’s leading casters for our clients. When you want precision-engineered solutions, contact us to learn more about the custom solutions we can manufacture for your business.