Why Our Wheels Work

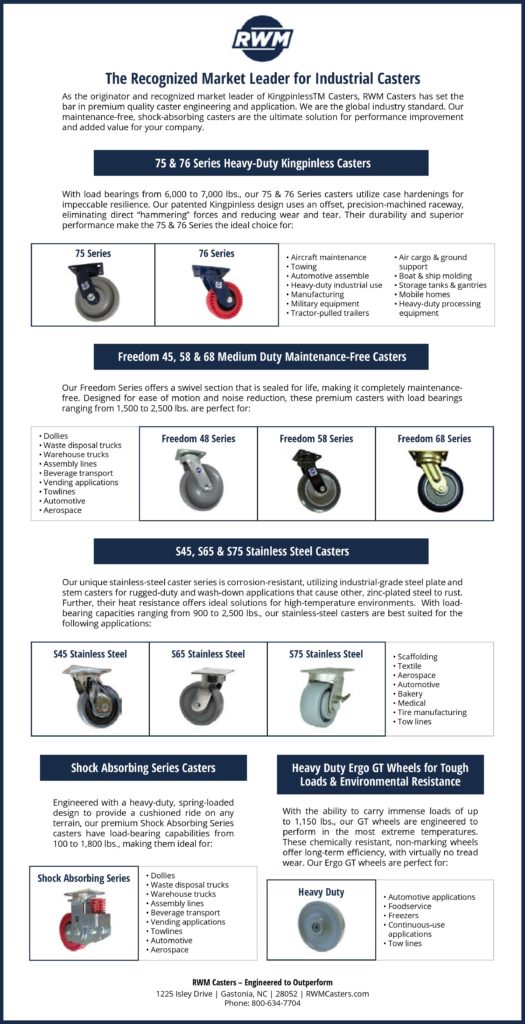

Choosing the right wheel is one of any business’s most important decisions. RWM Casters manufactures a comprehensive selection of precision-engineered wheels to deliver superior performance. From hospitals and healthcare facilities to manufacturing and industrial applications, our wheels improve handling, ease strain, and enhance safety.

We know it can be daunting to sort through your options to find the optimal wheel for your needs. This guide, coupled with our experts, can help you select wheels suitable for the conditions and applications inherent to your industry.

In terms of wheel mechanics, striking a balance is the key to designing and manufacturing a suitable caster. A balanced wheel accounts for the principles of wheel rotation and incorporates features that ensure even load distribution while minimizing impact on flooring. Our designers and engineers carefully consider every aspect of the design so that the finished wheel maintains superior traction, evenly distributes the load, minimizes strain on the operator, and increases stability in motion and stationary positions.

The Benefits of Using High-Quality Wheels

The right components are required to optimize productivity and equipment longevity. Our design and engineering teams have carefully considered factors, including temperature and weather conditions, floor type, operational stress, etc. The result is a superior wheel that delivers exceptional mobility, safety, and efficiency.

At RWM, our wheels deliver superior performance because of our many customizable features and options. With 16 different types of brakes and a broad range of bearings, we make it possible to create the perfect wheel for your needs.

Our bearing selection includes:

- Sealed precision ball bearing casters

- Annular ball bearing casters

- Flanged ball bearings casters

- Caged roller bearings

- Roller bearings

- Precision tapered roller bearings

- Delrin bearings

- Plastic sleeve (Celcon) bearings

- Oilite bearings

- Plain bore

Our Wheel Products

At RWM, our specialized wheels deliver exceptional durability and performance. We offer a broad selection of swivel, fixed, and heavy-duty wheels that can be customized to deliver dependable performance in a diverse range of operational conditions.

When you want dependable solutions, we recommend the following:

Torus wheels: Our Torus wheels feature a sealed precision bearing and are finished to a standard 92 Shore A hardness but can be customized to 85 Shore A or 70 Shore D. The design creates exceptional strength and ergonomics, noise reduction, and floor protection.

Omega wheels: One of our most popular and resilient designs, the Omega wheel is optimized for towline applications. It is available with a straight roller bearing, tapered, or ball bearings and is finished to a 95 Shore A Durometer hardness.

RWM Casters Signature™ Premium Wheel: Our Signature Premium Wheel features a lightweight, reinforced nylon core and a high-strength rubber tread, establishing the highest strength-to-weight ratio of any wheel in the industry. It is available with a straight roller or precision bearing and finished to a 70 Shore A hardness.

Why Choose Us?

The teams at RWM Casters are committed to delivering superior quality products and innovative solutions. When combined with our responsive customer service, you can rest assured that we will deliver customized solutions that help give your business a competitive advantage.

FAQs

What factors should my business consider when selecting a caster?

To enjoy the benefits of quality wheels, you’ll want to identify whether it’s for a light or heavy-duty application, the required load-bearing capacity, the floor surface, the optimal diameter and bearing type, the brake configuration, and the fittings. You’ll also want to account for special considerations, such as temperature, whether it’s for a medical application, etc.

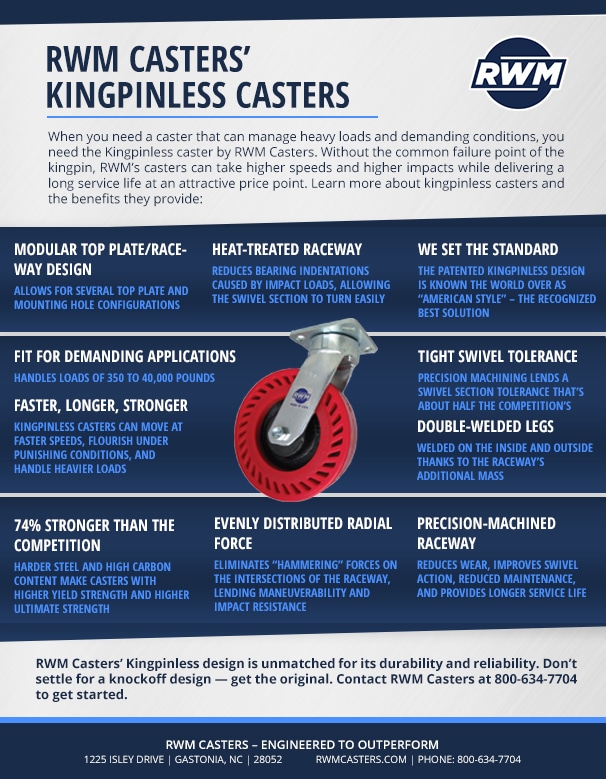

What are the advantages of a Kingpinless caster?

Kingpinless designs minimize raceway wear. They also enhance maneuverability and ergonomics, which helps protect loads and facilitates safer, more efficient movement.

What factors determine the required push/pull force?

The composition of the caster material, the type of bearings, the size of the caster, and the swivel lead are the main factors that determine push/pull force. At RWM, we aim to design balanced casters that minimize the push/pull force required to transport carts, equipment, etc.